Product Overview

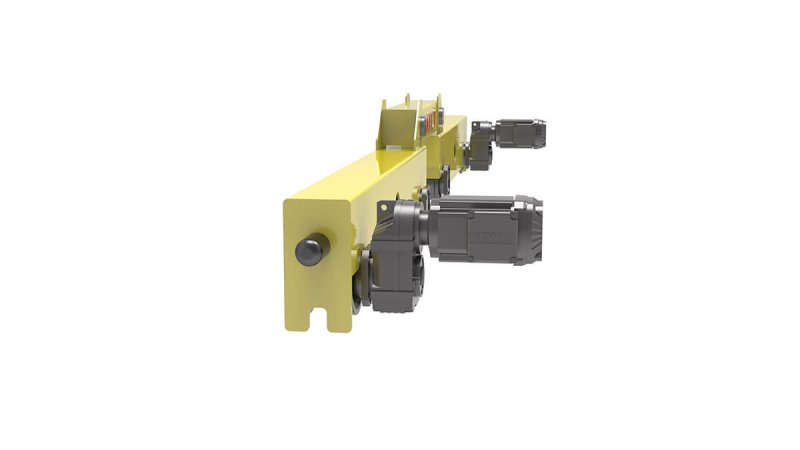

The European Standard Crane End Beam Group is a critical structural component for overhead crane systems, engineered to meet strict European safety and quality regulations. Built with high-strength steel and precision manufacturing, it provides reliable load support, enhanced stability, and long-term durability for demanding industrial applications.

Key Specifications

- Load Capacity: 1-500 tons (customizable)

- Material: High-strength steel (S355/S460)

- Standards: EN 13001, ISO 9001, CE certified

- Surface Treatment: Anti-corrosion coating

- Operating Temperature: -40°C to +60°C

- Safety Factor: 2.5:1 minimum

- Customization: Multiple sizes and configurations

Why Choose European Standard End Beam Groups?

European Compliance – Meets EN 13001 and CE safety standards

Superior Materials – Premium-grade steel construction

Precision Engineering – CNC machined components for accuracy

Long Service Life – 25+ years operational lifespan

Easy Integration – Compatible with major crane manufacturers

Global Warranty – Comprehensive quality assurance coverage

Structure & Engineering

Advanced Construction Features

- High-Strength Steel Beams – Premium S355/S460 grade steel

- Precision Machining – CNC manufacturing for dimensional accuracy

- Robust Connections – Welded and bolted joints for stability

- Anti-Corrosion Protection – Multi-layer protective coating system

Quality Assurance

- Material Traceability – Full documentation of steel origins

- Dimensional Inspection – CMM verification of all components

- Load Testing – 125% rated capacity testing

- Surface Quality – Professional coating inspection

Applications & Industries

Manufacturing & Production

- Assembly line overhead cranes

- Heavy machinery handling

- Raw material processing

Warehousing & Logistics

- Material handling systems

- Automated storage cranes

- Loading dock operations

Construction & Infrastructure

- Steel structure assembly

- Prefabricated component handling

- Construction site cranes

Heavy Industry & Metallurgy

- Steel mill operations

- Foundry applications

- Metal processing facilities

echnical Advantages

Structural Performance

- Load Distribution – Optimized stress distribution across beam structure

- Vibration Damping – Enhanced stability during crane operation

- Deformation Resistance – Maintains dimensional accuracy under load

- Fatigue Resistance – Designed for millions of load cycles

Installation Benefits

- Modular Design – Simplified assembly and installation

- Universal Mounting – Compatible with standard crane configurations

- Quick Replacement – Minimal downtime during maintenance

- Flexible Configurations – Customizable to specific requirements

Compliance & Certification

European Standards

- EN 13001 – Crane safety requirements

- EN 1090 – Structural steel execution standards

- ISO 9001 – Quality management systems

- CE Marking – European conformity certification

Quality Control

- Factory Inspections – Third-party quality audits

- Material Certificates – Mill test certificates included

- Weld Quality – NDT testing of critical joints

- Final Inspection – 100% quality verification

Contact Us Professional Engineering & Installation Services