Introduction to Overhead Crane Systems

As the backbone of today’s material handling, bridge cranes are found in manufacturing plants, warehouses, and heavy industries around the world. Choosing a single-girder or double-girder configuration is one of the most fundamental decisions in crane purchasing, but it also has a profound impact on operational efficiency, safety, and long-term costs.

Industrial facilities processing everything from automotive components to steel fabrication rely heavily on these systems. For instance, Boeing’s aircraft assembly facilities utilize massive double-girder systems capable of handling entire aircraft sections weighing hundreds of tons, while smaller manufacturing plants may opt for single-girder solutions for handling raw materials and finished products.

Their differences are not just structural differences. Each configuration has its own unique advantages. If you want to buy an ideal product, then understanding the differences in their advantages will be crucial for your decision-making. Of course, if their individual advantages still cannot meet your needs, we also provide non-standard parts customization services. You can tell us your needs and we will provide you with solutions and detailed quotes as soon as possible.

Modern bridge crane technology has integrated advanced control systems, frequency conversion systems, and reliable safety systems. However, the configuration of single-beam and double-beam cranes is still as important as it was decades ago, serving different application scenarios. The following content can help you understand the differences between single-beam and double-beam cranes and provide guidance for your decision making.

Understanding Single-Girder Overhead Cranes

Single-girder overhead cranes feature a streamlined design where the hoist travels along the bottom flange of a single main girder beam. Its compact structure significantly saves costs and provides reliable lifting, suitable for light to medium lifting applications. In addition, its compact design can maximize the available hook height in space-constrained scenarios.

The structural simplicity of single-girder systems translates into several practical advantages. Manufacturing facilities producing consumer electronics, such as Samsung’s smartphone assembly plants, often utilize single-girder cranes for handling component trays, packaging materials, and finished products. These systems typically handle loads ranging from 500 pounds to 20 tons, making them suitable for a vast majority of general industrial applications.

Single-girder overhead cranes involve fewer components and a simpler manufacturing process. The main girder integrates the dual functions of structural support and trolley track, simplifying the overall design and reducing material requirements. This design significantly reduces project complexity and installation time.

Control systems for single-girder cranes have advanced considerably, with modern installations featuring radio remote controls, variable speed operation, and integrated safety systems. A textile manufacturing facility in North Carolina recently upgraded their material handling system with single-girder cranes equipped with precision positioning controls, enabling automated fabric roll handling with positioning accuracy within inches.

The relatively simple structure of a single-girder overhead crane makes it ideal for applications that require frequent reconfiguration or expansion. Compared to a double-girder overhead crane, a single-girder crane is lighter and easier to reposition, requiring only minimal reinforcement of the existing building structure.

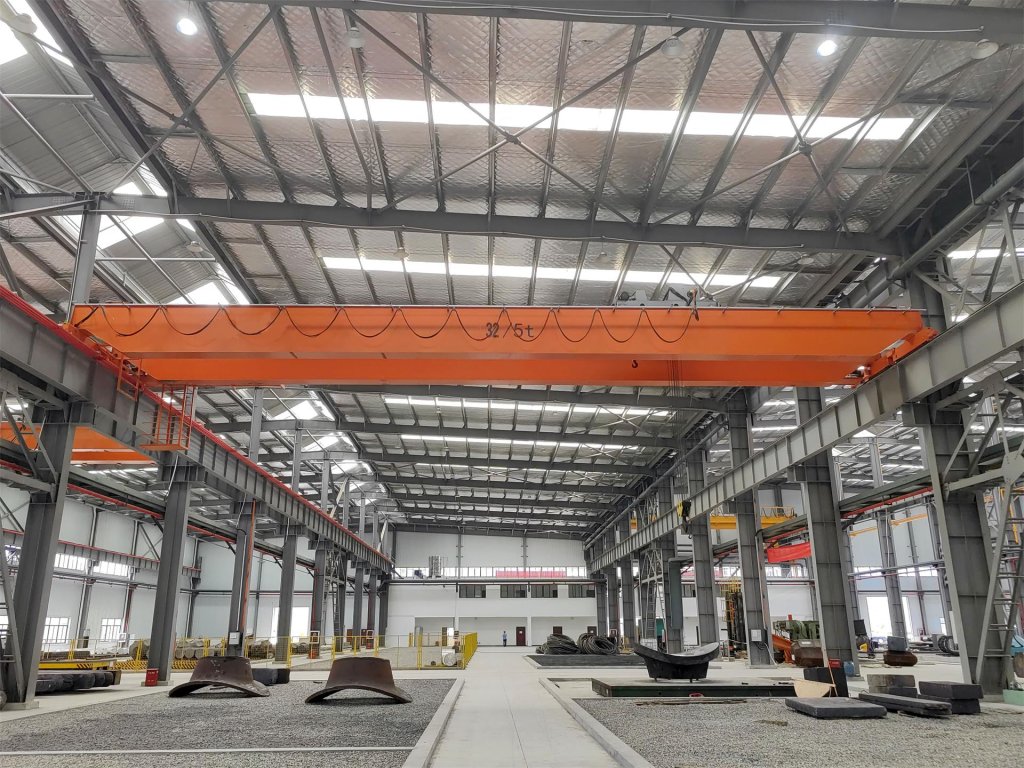

Understanding Double-Girder Overhead Cranes

This structural configuration provides better structural strength and lifting capacity than single-girder cranes. If you have high lifting precision and reliability requirements, then a double-girder bridge crane will be your ideal choice.

The architectural elegance of double-girder systems becomes apparent in heavy industry applications. Steel mills, such as those operated by Nucor Corporation, rely on double-girder cranes with capacities exceeding 500 tons to handle molten metal ladles, massive steel coils, and heavy machinery components. These systems operate in extreme environments with temperatures exceeding 2,000°F, demonstrating the robust nature of double-girder construction.

Structural engineering principles favor double-girder designs for applications involving long spans and heavy loads. The dual-beam configuration distributes loads more effectively across the runway structure, reducing deflection and improving overall system rigidity. This enhanced stability proves crucial in precision manufacturing applications where load positioning accuracy directly impacts product quality.

Modern double-girder cranes incorporate sophisticated technologies including anti-sway systems, load moment indicators, and automated material tracking systems. An automotive stamping plant in Michigan utilizes double-girder cranes equipped with servo-controlled positioning systems capable of placing heavy steel coils with millimeter precision, enabling fully automated material handling workflows.

The operational advantages of double-girder systems extend beyond raw lifting capacity. The top-running configuration provides maximum hook height utilization, allowing facilities to maximize their vertical storage capacity. Additionally, the ability to incorporate multiple hoists on a single bridge enables complex lifting operations involving coordinated movements and tandem lifting applications.

Load Capacity Comparison and Applications

Load capacity represents the most significant differentiating factor between Single-girder cranes are usually used in scenarios where lifting requirements are 1-25 tons. Double-girder cranes can easily handle lifting requirements from 25 tons to hundreds of tons, and can even be seen in special application scenarios with lifting requirements of more than 1,000 tons.

The relationship between crane capacity and structural requirements follows engineering principles that favor different configurations at various load ranges. A pharmaceutical manufacturing facility in New Jersey operates single-girder cranes rated at 5 tons for handling raw material containers and mixing vessels. The compact design allows multiple cranes to operate in the same facility without interfering with production equipment or personnel movement.

At the opposite end of the spectrum, shipbuilding facilities require double-girder systems capable of handling massive vessel components. Newport News Shipbuilding utilizes double-girder cranes with capacities exceeding 900 tons for positioning aircraft carrier sections during assembly. These systems incorporate advanced load monitoring and control technologies to ensure safe operation despite the enormous forces involved.

Duty cycle considerations significantly impact capacity selection decisions. Manufacturing facilities with continuous operations require cranes designed for frequent lifting cycles, often necessitating oversized capacity ratings to ensure component longevity. A paper mill in Oregon operates 15-ton single-girder cranes sized for 10-ton working loads, providing a 50% safety margin that extends equipment life despite continuous operation.

Load distribution characteristics also influence capacity selection. Double-girder systems excel at handling loads with unusual geometries or unbalanced weight distributions. A wind turbine manufacturing facility uses double-girder cranes to handle turbine nacelles weighing 300 tons, where the irregular load shape would create stability challenges for single-girder systems.

Specialized applications often require custom capacity solutions. Research facilities handling sensitive equipment may specify lower capacity ratings with enhanced precision controls, while scrapyard operations might require maximum capacity systems designed for rugged service conditions.

Span Limitations and Structural Considerations

Span refers to the distance between the two support points of the crane. It is another key difference between single-girder and double-girder bridge cranes. Single-girder cranes are suitable for spans of about 100 feet, while double-girder bridge cranes support larger spans, generally exceeding 150 feet, and some can even exceed 300 feet.

Structural mechanics governing span limitations relate to beam deflection, load distribution, and support requirements. A warehouse distribution center in Texas operates single-girder cranes spanning 80 feet for handling packaged goods and palletized materials. The single-beam design provides adequate structural performance while minimizing building modification requirements and installation costs.

Large-scale manufacturing operations often require extensive span capabilities to serve multiple production areas with a single crane system. An aircraft manufacturing facility operates double-girder cranes spanning 200 feet, enabling complete coverage of assembly bays where commercial aircraft are constructed. The dual-beam configuration provides the structural rigidity necessary to maintain positioning accuracy across the entire span.

Engineering calculations for span determination involve complex analysis of deflection limits, dynamic loading conditions, and fatigue considerations. Professional structural engineers utilize finite element analysis software to optimize girder dimensions and support spacing for specific applications. A steel fabrication shop in Pennsylvania worked with crane manufacturers to design a 120-foot span double-girder system that minimized building column requirements while providing necessary lifting capacity.

Building integration challenges increase proportionally with span requirements. Longer spans require more substantial runway support structures, potentially necessitating building modifications or reinforcements. Existing facilities considering crane upgrades must evaluate their structural capacity to support longer span systems, often requiring professional structural analysis.

Single-girder bridge cranes are suitable for shorter span scenarios and have lower cost advantages; double-girder bridge cranes become more economical as the span increases, and this feature usually becomes more prominent after exceeding 75 feet. The crossover point varies based on specific application requirements, building characteristics, and local installation costs.

Height Requirements and Hook Travel

Hook height is a key design consideration that directly impacts equipment efficiency. Single-girder overhead cranes, due to their unique design, offer high headroom within limited spaces. Double-girder cranes, on the other hand, sacrifice vertical clearance to maintain structural integrity.

Headroom requirements differ significantly between configurations. Single-girder systems typically require 24-30 inches of headroom above the girder, while double-girder systems need 36-48 inches depending on hoist specifications. A electronics assembly facility with 20-foot ceiling height maximized their hook travel by selecting single-girder cranes, achieving 18 feet of usable lifting height compared to 16 feet with equivalent double-girder systems.

Vertical clearance optimization becomes critical in retrofit applications where existing buildings cannot be modified. An automotive parts manufacturer upgraded their material handling system within an existing facility by choosing single-girder cranes that provided adequate hook height without requiring costly building modifications. The installation maintained existing production schedules while improving material handling efficiency.

Multi-level facilities present unique hook travel challenges requiring specialized design approaches. A multi-story manufacturing facility in Ohio utilizes double-girder cranes with extended lift heights serving multiple floor levels through strategically positioned openings. The enhanced structural capability of double-girder systems enables safe operation across extended vertical ranges.

Precision manufacturing applications often require maximum hook travel to accommodate varying product sizes and storage configurations. A injection molding facility uses single-girder cranes with full-height lift capability to move products from floor-level production equipment to mezzanine-level storage areas, maximizing facility space utilization.

For safety reasons, sufficient clearance should be left above the upper hook position to prevent collision with building structures or other equipment. Although modern cranes are equipped with limit switches and anti-collision systems, it is crucial to leave appropriate clearance to prevent accidents.

Cost Analysis: Initial Investment vs. Long-term Value

Cost considerations encompass initial acquisition costs, installation expenses, and long-term operational costs including maintenance, energy consumption, and productivity impacts. Single beam systems offer lower initial costs, but in high-demand applications,double-beam systems will provide better long-term value.

Initial acquisition costs favor single-girder systems across most capacity ranges. A comparative analysis for a 10-ton capacity crane reveals single-girder systems costing approximately 25-35% less than equivalent double-girder configurations. This cost advantage stems from reduced material requirements, simplified fabrication processes, and less complex installation procedures.

A furniture manufacturing facility in North Carolina selected single-girder cranes based primarily on cost considerations. The $125,000 investment provided adequate capacity for their wood panel and finished furniture handling requirements, compared to $180,000 for equivalent double-girder systems. The cost savings enabled the company to install three cranes instead of two, improving overall facility coverage.

Installation costs vary significantly based on building modifications required and system complexity. Single-girder systems typically install faster with less disruption to ongoing operations. A food processing facility completed single-girder crane installation over a weekend shutdown, while equivalent double-girder systems would have required extended facility closure for runway construction.

Long-term operational costs include energy consumption, maintenance requirements, and productivity considerations. Double-girder systems often demonstrate superior efficiency in high-utilization applications. A steel service center analysis revealed their double-girder cranes provided 15% higher productivity due to faster operating speeds and enhanced positioning accuracy, justifying the higher initial investment through improved operational efficiency.

Maintenance cost analysis requires evaluation of component accessibility, replacement part availability, and system reliability. Single-girder systems generally offer easier maintenance access, while double-girder systems may provide longer component life in demanding applications. A chemical processing facility tracks maintenance costs revealing their single-girder cranes require 20% less annual maintenance expense due to simplified component access.

Total cost of ownership calculations must consider equipment life expectancy, productivity impacts, and facility-specific factors. Professional cost analysis tools help quantify these factors for specific applications, enabling data-driven decision making.

Installation Complexity and Building Requirements

Installation requirements differ substantially between single-girder and double-girder overhead crane systems, affecting project timelines, facility disruption, and building modification costs. Single-beam systems are simple to install, while double-beam systems require more comprehensive preparation and structural considerations.Building structural requirements represent the primary installation differentiator. Single-girder systems exert lower loads on runway structures, often enabling installation in existing buildings without significant modifications. A pharmaceutical manufacturing facility installed single-girder cranes in their existing production area using the original building columns with minor reinforcement, completing the project without interrupting critical production schedules.

Foundation and runway construction requirements scale with system size and capacity. Double-girder installations typically require more substantial foundations and runway structures to accommodate higher loads and longer spans. A power generation equipment manufacturer invested $300,000 in building modifications to support new double-girder cranes, including foundation reinforcement and new runway beam installation.

Installation timeline considerations affect production scheduling and project planning. Single-girder systems often install in 2-3 days per crane, while double-girder systems may require 1-2 weeks depending on complexity and site conditions. An aerospace components manufacturer scheduled their single-girder crane installation during planned maintenance shutdown, minimizing production impact.

Specialized installation equipment requirements vary based on crane size and building access limitations. Large double-girder systems may require multiple mobile cranes for assembly, while single-girder systems often install using smaller equipment. A machine shop installed their single-girder crane using a forklift and come-along winches, avoiding expensive mobile crane rental fees.

Coordination with other building systems becomes critical during installation. Modern facilities integrate cranes with fire suppression systems, building automation networks, and safety systems. A electronics manufacturing facility coordinated their crane installation with existing clean room requirements, incorporating specialized filtration and contamination control measures.

Quality control and testing procedures ensure safe operation following installation. Both systems require load testing, functional verification, and safety system validation. Professional installation teams follow OSHA and ANSI standards to ensure compliant installations regardless of system type.

Maintenance Requirements and Operational Costs

Maintenance requirements and operational costs significantly impact the total cost of ownership for overhead crane systems. Single-girder and double-girder configurations present different maintenance challenges, component accessibility, and long-term reliability characteristics that influence operational expenses.

Routine maintenance accessibility favors single-girder systems in most applications. The under-hung hoist configuration places critical components at ground level or easily accessible elevated positions. A automotive parts warehouse reports their single-girder crane maintenance requires 40% less time than previous double-girder systems due to improved component access for inspections, lubrication, and adjustments.

Component replacement procedures differ substantially between configurations. Single-girder systems typically enable hoist removal from below, while double-girder systems may require overhead access or specialized lifting equipment for component replacement. A steel fabrication facility maintains service platforms on their double-girder cranes to facilitate routine maintenance, representing additional infrastructure investment.

Predictive maintenance technologies increasingly influence operational cost analysis. Modern crane systems incorporate condition monitoring sensors, vibration analysis equipment, and automated diagnostic systems. A chemical processing plant utilizes predictive maintenance systems on their double-girder cranes, reducing unplanned downtime by 60% through early detection of potential component failures.

Energy consumption analysis reveals operational differences between configurations. Double-girder systems often demonstrate superior energy efficiency due to reduced friction losses and optimized motor sizing. A warehouse distribution center measured 12% lower energy consumption with their new double-girder cranes compared to replaced single-girder systems, despite higher capacity ratings.

Maintenance staff training requirements vary based on system complexity and safety considerations. Double-girder systems may require specialized training for high-elevation maintenance procedures, while single-girder systems often utilize standard industrial maintenance practices. A manufacturing facility invested in specialized training for their maintenance staff following double-girder crane installation, improving safety and maintenance efficiency.

Spare parts inventory management affects operational continuity and costs. Single-girder systems often utilize standard components with broad availability, while specialized double-girder systems may require unique parts with longer lead times. Strategic spare parts planning ensures operational continuity regardless of system type.

Safety Features and Compliance Standards

Safety considerations are particularly important in the design, selection, and operation of bridge cranes. Modern bridge cranes integrate advanced safety technologies, but due to design differences between different models, they have different safety features and compliance requirements.

Regulatory compliance requirements apply to both system types through OSHA standards, ANSI specifications, and local building codes. However, implementation approaches differ based on system configuration and application requirements. A chemical processing facility enhanced their single-girder crane safety systems with redundant limit switches, emergency stops, and operator protection systems to meet stringent industry safety requirements.

Load handling safety features vary between configurations. Double-girder systems typically provide enhanced stability for challenging loads due to their superior structural rigidity. A steel mill utilizes double-girder cranes with advanced anti-sway systems for handling molten metal ladles, where load stability directly impacts personnel safety and facility protection.

Operator visibility considerations influence safety performance significantly. Single-girder systems may provide better sightlines in some applications due to their streamlined configuration, while double-girder systems can accommodate operator cabs for improved control in demanding applications. An automotive assembly plant installed double-girder cranes with enclosed operator cabs to protect personnel from welding operations while maintaining optimal visibility.

Emergency response procedures require specific consideration for each system type. Single-girder systems typically enable faster emergency access due to ground-level component locations, while double-girder systems may require specialized rescue procedures for elevated maintenance activities. Comprehensive emergency response training addresses system-specific challenges.

Advanced safety technologies increasingly standard on modern installations include collision avoidance systems, load moment monitoring, and automated safety checks. A aerospace manufacturing facility utilizes double-girder cranes with integrated safety systems that automatically prevent overload conditions and maintain safe working zones around personnel and equipment.

Ensuring safe operation requires ongoing safety training, clear hazard signs, and accident prevention plans. Regardless of the system configuration, regular safety reviews should be conducted and processes continuously optimized to ensure the crane system remains safe.

Performance and Precision in Material Handling

Due to the differences in performance between single-girder and double-girder overhead cranes, each configuration offers unique advantages in specific operating requirements or performance in applications such as precise material handling, high-speed operation and heavy duty cycles.

Positioning accuracy represents a critical performance parameter in precision manufacturing applications. Double-girder systems typically provide superior accuracy due to enhanced structural rigidity and reduced deflection under load. A semiconductor manufacturing facility utilizes double-girder cranes with servo-controlled positioning systems achieving positional accuracy within 0.25 inches for handling sensitive equipment and materials.

Operating speed capabilities vary based on system design and application requirements. Single-girder systems often achieve adequate speeds for general applications, while double-girder systems can accommodate higher speeds when required for productivity enhancement. A logistics distribution center operates high-speed double-girder cranes capable of 600 feet per minute bridge travel to maximize throughput in automated storage and retrieval operations.

The double-beam configuration ensures load stability during operation through excellent structural design and an optional anti-sway system, providing guarantees for product quality and operational safety. A glass manufacturing facility requires exceptional load stability for handling large glass sheets, necessitating double-girder cranes with active anti-sway control systems.

Dynamic response characteristics influence performance in applications involving frequent starts, stops, and direction changes. Modern variable frequency drive systems optimize acceleration and deceleration curves for both configurations, but fundamental structural differences affect overall dynamic behavior. A automotive stamping plant utilizes single-girder cranes optimized for rapid cycle operations handling small components between processing stations.

Precision control systems enable advanced material handling capabilities including automated operation, coordinated multi-crane movements, and integration with facility management systems. A aerospace composites facility operates coordinated double-girder cranes with millimeter-level positioning accuracy for automated layup operations, demonstrating advanced precision capabilities.

Performance monitoring and optimization systems provide operational insights enabling continuous improvement. Modern installations incorporate data collection systems tracking cycle times, positioning accuracy, and energy consumption to optimize performance and identify improvement opportunities.

Industry-Specific Applications and Case Studies

Different industries present different material handling challenges that require cranes with specific configurations to meet varying operational needs, environmental conditions, and performance expectations. Understanding industry-specific applications provides valuable insights for system selection decisions.

Steel and Metal Processing facilities predominantly utilize double-girder systems due to extreme load requirements and harsh operating environments. ArcelorMittal’s steel production facilities operate double-girder cranes with capacities exceeding 400 tons for handling steel coils, slabs, and finished products. These systems incorporate specialized features including heat-resistant components, explosion-proof electrical systems, and advanced load monitoring capabilities to ensure safe operation in challenging environments.

Automotive Manufacturing applications span both configuration types depending on specific requirements. Ford’s assembly plants utilize single-girder cranes for handling body panels, engines, and components weighing up to 15 tons. The streamlined design enables multiple cranes to operate in crowded assembly areas without interference. Conversely, automotive stamping operations require double-girder systems capable of handling massive steel coils and press dies weighing hundreds of tons.

Aerospace and Defense applications demand exceptional precision and reliability. Boeing’s aircraft assembly facilities utilize specialized double-girder cranes with positioning accuracies measured in millimeters for handling aircraft sections during assembly. These systems incorporate advanced control technologies, redundant safety systems, and specialized lifting attachments designed for complex aerospace components.

Paper and Pulp industries operate in challenging environments requiring specialized crane configurations. A paper mill in Washington operates single-girder cranes with corrosion-resistant coatings and sealed electrical components for handling paper rolls in high-humidity environments. The systems feature specialized lifting attachments designed for safe paper roll handling without product damage.

Chemical and Petrochemical facilities require explosion-proof crane systems for safe operation in hazardous environments. A chemical processing plant utilizes double-girder cranes with Class I, Division 1 electrical ratings for handling chemical processing equipment and materials. These systems incorporate specialized safety features including spark-resistant components and emergency shutdown systems.

Renewable Energy applications present unique handling challenges for large, irregularly-shaped components. Wind turbine manufacturing facilities utilize double-girder cranes for handling turbine components including blades exceeding 150 feet in length and nacelles weighing over 300 tons. These specialized applications require custom lifting attachments and coordinated multi-crane operations.

Future-Proofing and Scalability Considerations

Future-proofing considerations influence crane system selection decisions as facilities plan for evolving operational requirements, technology advancement, and business growth. Single-girder and double-girder systems offer different scalability characteristics and upgrade potential that affect long-term value.

Technology integration capabilities vary between configurations based on structural capacity and design flexibility. Double-girder systems typically accommodate advanced technologies including automated guided vehicles, robotic material handling systems, and facility-wide automation networks more readily than single-girder configurations. A automotive parts manufacturer installed double-girder cranes with provisions for future robotic integration, enabling gradual automation implementation as technology and business requirements evolve.

Capacity expansion possibilities require evaluation of existing infrastructure and system design margins. Single-girder systems often reach practical capacity limits sooner than double-girder alternatives, potentially necessitating complete system replacement for significant capacity increases. A machinery manufacturer upgraded from single-girder to double-girder cranes to accommodate larger equipment handling requirements as their product line expanded.

Facility expansion considerations affect crane system scalability and modification potential. Modular crane designs enable system extension and reconfiguration to serve expanded facilities. A electronics manufacturer designed their double-girder crane system with modular runway construction, enabling economical system extension as their facility expanded over time.

Digital transformation initiatives increasingly influence crane system selection as facilities integrate material handling with enterprise resource planning systems, predictive maintenance programs, and operational analytics platforms. Modern crane systems incorporate data collection capabilities, remote monitoring systems, and cloud connectivity to support digital transformation objectives.

Sustainability requirements drive considerations for energy efficiency, environmental impact, and lifecycle sustainability. Advanced crane systems feature regenerative braking, LED lighting, and energy-efficient drive systems reducing environmental impact and operational costs. A distribution center specified energy-efficient double-girder cranes as part of their sustainability initiative, achieving 20% reduction in material handling energy consumption.

Over time, regulatory evolution of cranes will also affect their design and operating requirements. Consideration must be given to potential regulatory changes that may affect safety requirements, environmental requirements and operability standards.Flexible crane systems accommodate regulatory evolution through upgradeable control systems and modifiable safety features.

Decision Matrix: Choosing the Right System

Systematic evaluation of single-girder versus double-girder overhead crane systems requires comprehensive analysis of operational requirements, facility characteristics, and economic considerations. A structured decision matrix approach ensures objective evaluation of all relevant factors.

Generally speaking, load requirements below 20 tons tend to choose a single-beam system, while loads over 25 tons usually require a double-beam configuration. However, in addition to load requirements, other factors should also be considered, such as working frequency, accuracy requirements, span limitations, etc. Only by weighing all factors can the best selection decision be made.

Facility characteristics including building height, span requirements, and structural capacity directly impact system selection. Facilities with limited headroom benefit from single-girder systems, while long-span applications typically require double-girder configurations. A decision matrix scoring system weights these factors according to specific application priorities.

Economic analysis encompasses initial acquisition costs, installation expenses, operational costs, and long-term value considerations. Single-girder systems typically offer lower initial costs, while double-girder systems may provide superior long-term value in demanding applications. Comprehensive life-cycle cost analysis quantifies these trade-offs for specific applications.

Performance requirements including positioning accuracy, operating speed, and load stability influence system selection. Applications requiring exceptional precision typically favor double-girder systems, while general material handling applications often achieve adequate performance with single-girder configurations.

Future requirements consideration ensures selected systems accommodate anticipated operational evolution, facility expansion, and technology advancement. Facilities planning significant growth or operational changes may benefit from double-girder systems offering greater expansion potential.

Risk assessment evaluates potential consequences of system selection decisions including operational disruption, safety implications, and economic impact. Conservative approaches may favor proven configurations with extensive service history, while innovative applications may justify advanced system features.

Professional consultation with experienced crane manufacturers, structural engineers, and material handling specialists provides valuable expertise for complex selection decisions. Collaborative evaluation processes ensure comprehensive consideration of all relevant factors and access to specialized knowledge.

Conclusion and Expert Recommendations

The selection between single-girder and double-girder overhead crane systems represents a complex decision requiring careful evaluation of multiple technical, economic, and operational factors. Each configuration offers distinct advantages that align with specific application requirements and facility characteristics.

Single-girder overhead cranes excel in applications requiring cost-effective solutions for light to moderate lifting requirements. Their streamlined design, simplified installation, and superior hook height utilization make them ideal for general manufacturing, warehouse operations, and facilities with limited headroom. The lower initial investment and reduced maintenance complexity provide compelling advantages for budget-conscious operations with straightforward material handling requirements.

Double-girder overhead cranes represent the optimal solution for demanding applications requiring heavy lifting capacity, long spans, and exceptional precision. Their superior structural characteristics, enhanced stability, and advanced technology integration capabilities justify higher initial costs through improved performance and operational flexibility. Industries including steel processing, aerospace manufacturing, and heavy equipment production benefit significantly from double-girder capabilities.

Economic analysis must consider total cost of ownership including initial acquisition, installation, operational costs, and productivity impacts. While single-girder systems offer lower initial costs, double-girder systems may provide superior long-term value in high-utilization applications through enhanced efficiency and reduced operational constraints.

Technology advancement continues influencing crane system capabilities and selection criteria. Modern systems incorporate advanced control technologies, predictive maintenance capabilities, and automation integration features that enhance performance regardless of configuration type. Future-proofing considerations favor systems designed to accommodate evolving technology and operational requirements.

Safety considerations remain paramount regardless of system selection. Both configurations can achieve exceptional safety performance through proper design, installation, maintenance, and operator training. Regulatory compliance and industry best practices ensure safe operation throughout equipment life cycles.

Professional expertise proves invaluable for complex selection decisions. Collaboration with experienced crane manufacturers, structural engineers, and material handling specialists ensures comprehensive evaluation of technical requirements, facility characteristics, and operational objectives. This collaborative approach optimizes system selection decisions and implementation success.

The material handling industry continues evolving through technological advancement, regulatory development, and changing operational requirements. Successful crane system selection requires balancing current needs with future flexibility, ensuring selected systems provide sustained value throughout their operational life. Whether choosing single-girder or double-girder configurations, thorough analysis and professional expertise enable optimal material handling solutions that enhance productivity, safety, and operational efficiency.

This comprehensive analysis provides facility managers, engineers, and decision-makers with the technical knowledge and practical insights necessary for informed overhead crane system selection. Professional consultation remains recommended for specific applications requiring detailed engineering analysis and customized solutions.