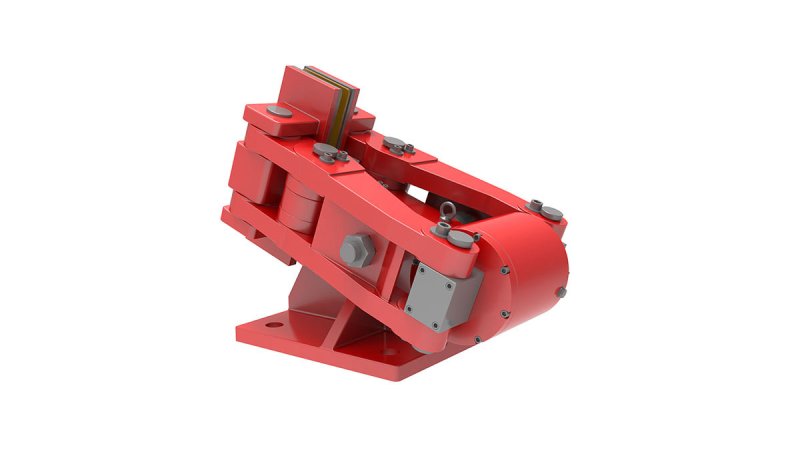

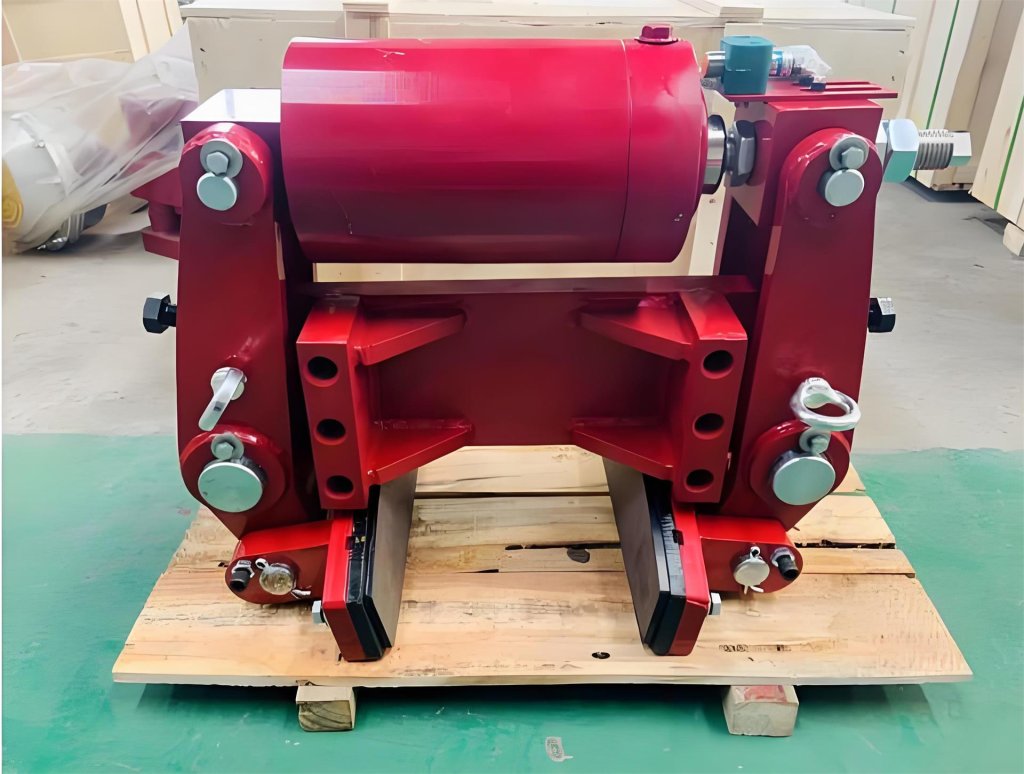

Crane Brake 50-50,000 Nm – Reliable Safety Solution

Introduction

The Crane Brake is a vital safety component for industrial crane systems, controlling motion and securing loads. Our range includes electromagnetic, hydraulic, and mechanical brakes engineered for reliability, safety, and efficiency across all applications.

Technical Specifications and Performance Features

Provides 50-50,000 Nm torque with 0.1-0.5s response. Key specs:

- Braking Torque: 50-50,000 Nm

- Response Time: 0.1-0.5 seconds

- Operating Voltage: 24V-480V DC/AC

- Temperature Range: -40°C to +200°C

- Protection Rating: IP54/IP65/IP67

- Safety Factor: 2:1 minimum

- Certification: CE, UL, CSA, ISO

- Brake Type: Electromagnetic or Hydraulic

- Brake Efficiency: 90 ~ 100%

- Maintenance Interval: 6 ~ 12 Months

- Design Standard: GB3811

Ensures precise control in extreme conditions.

Mechanical Design Features

- Premium materials: Hardened steel components

- Corrosion resistance: Protective coatings

- Precision CNC: Machined for accuracy

- Self-aligning bearings: Extended life

- Modular design: Easy replacement

Operational Features

- Fast response: <0.2s emergency stops

- Variable torque: Precise load control

- Smooth action: Progressive braking

- High efficiency: 90-100%

- Self-adjusting: Wear compensation

Safety and Protection Systems

- Fail-safe spring-applied: Engages on power loss

- Dual circuits: Redundant safety

- Load monitoring: Overload prevention

- Anti-lock/ABS: Wheel lock-up prevention

- IP65 sealing: Weather-resistant

Installation and System Integration

- Modular setup: Quick install

- Universal fit: Overhead/gantry cranes

- Easy access: Maintenance-friendly

- Standard parts: Common replacements

Control System Compatibility

- Precision interface: Variable force

- Crane controls: Standard integration

- Programmable: Operational modes

- Sensor options: Predictive monitoring

Technical Performance Data

- Torque: 50-50,000 Nm

- Response: 0.1-0.5s

- Voltage: 24V-480V

- Temperature: -40°C to +200°C

- Protection: IP54/IP65/IP67

- Safety Factor: 2:1 min

- Efficiency: 90-100%

- Cycles: 2M+

- Standards: GB3811, CE, UL, CSA, ISO

Quality Manufacturing Standards

- Robust build: Premium components

- 100% inspection: Factory testing

- Asbestos-free: Eco-safe materials

- Certifications: CE, OSHA, ANSI, ISO

- Warranty: Standard coverage

Application Suitability

- Manufacturing: Production lines, assembly

- Construction: Tower/mobile cranes

- Steel Industry: Mill/foundry ops

- Ports/Logistics: Container/bulk handling

Brake Types

- Electromagnetic: 1-100 tons, fast response

- Hydraulic: 10-500+ tons, high torque

- Mechanical: 0.5-50 tons, low maintenance

Technical Support and Configuration

- Installation support: Professional guidance

- Customization: Torque/voltage options

- Documentation: Specs/guides

- Maintenance: 6-12 month intervals

Maintenance Requirements

- Inspections: Wear, seals, alignment

- Self-adjusting: Minimal intervention

- Sensor monitoring: Optional predictive

- Standard protocols: Reduce downtime

Call to Action

Secure your crane with Crane Brake systems. Contact us for custom solutions and installation.