Gantry Crane: Common Faults, Solutions, and Maintenance Techniques | 2025 Complete Guide

Gantry crane operators and maintenance teams face numerous challenges maintaining reliable equipment performance under demanding industrial conditions. Equipment downtime from unexpected failures costs manufacturers thousands of dollars hourly while compromising production schedules and safety. Understanding common gantry crane faults, implementing effective solutions, and establishing comprehensive maintenance programs significantly reduces unplanned outages while extending equipment service life. This detailed guide examines frequent mechanical, electrical, and structural problems affecting gantry crane systems. It provides proven troubleshooting methodologies and preventive maintenance strategies. Whether managing single installations or multiple gantry crane fleets, mastering these fundamental maintenance principles ensures optimal equipment reliability, operational safety, and cost-effective asset management throughout the equipment lifecycle.

Understanding Gantry Crane System Components and Function

Core Structural Elements of Gantry Cranes

Gantry crane structures consist of horizontal bridge beams spanning between vertical supporting legs that travel on ground-level rails or paved surfaces. This configuration distinguishes gantry cranes from overhead bridge cranes requiring elevated runway beams attached to building structures. The self-supporting design enables gantry crane installations in outdoor yards, shipping terminals, and facilities lacking adequate building structures for overhead systems. Single girder gantry cranes utilize one main beam with under-hung hoist trolleys. Double girder configurations feature two parallel beams providing superior capacity and rigidity for heavy-duty applications.

Supporting legs transfer all operational loads including equipment weight, lifted loads, and dynamic forces into foundation systems or ground surfaces. These structural members incorporate connection points for bridge beams, wheel assemblies enabling travel motion, and lateral bracing preventing structural deformation. Leg height determines maximum lifting elevation. Taller structures accommodate higher hook positions but require more robust designs resisting wind loads and maintaining stability. Additionally, some gantry crane designs feature cantilever extensions beyond supporting legs increasing operational coverage without proportionally expanding the travel corridor width.

Mechanical Drive Systems and Components

Gantry crane mechanical systems include hoisting mechanisms lifting loads vertically, trolley drives moving loads along bridge spans, and long travel drives propelling entire structures along rails. Each motion system incorporates electric motors, gearboxes reducing speed while increasing torque, brake assemblies controlling motion and holding loads, and coupling mechanisms connecting components. Wire rope or chain hoisting systems wind onto drums or sprockets. Multiple reeving configurations provide mechanical advantage trading speed for increased capacity.

Wheel assemblies enable gantry crane travel, typically featuring four to eight wheels distributed across supporting legs. These critical components incorporate bearings supporting radial and thrust loads, wheel treads contacting rail surfaces, and mounting brackets attaching assemblies to structural frames. Drive wheels connect to motors through gearboxes, while idler wheels rotate freely. Proper wheel alignment, adequate lubrication, and correct rail gauge prove essential for smooth operation and preventing premature wear. Furthermore, wheel flange designs guide travel motion preventing derailment during operation.

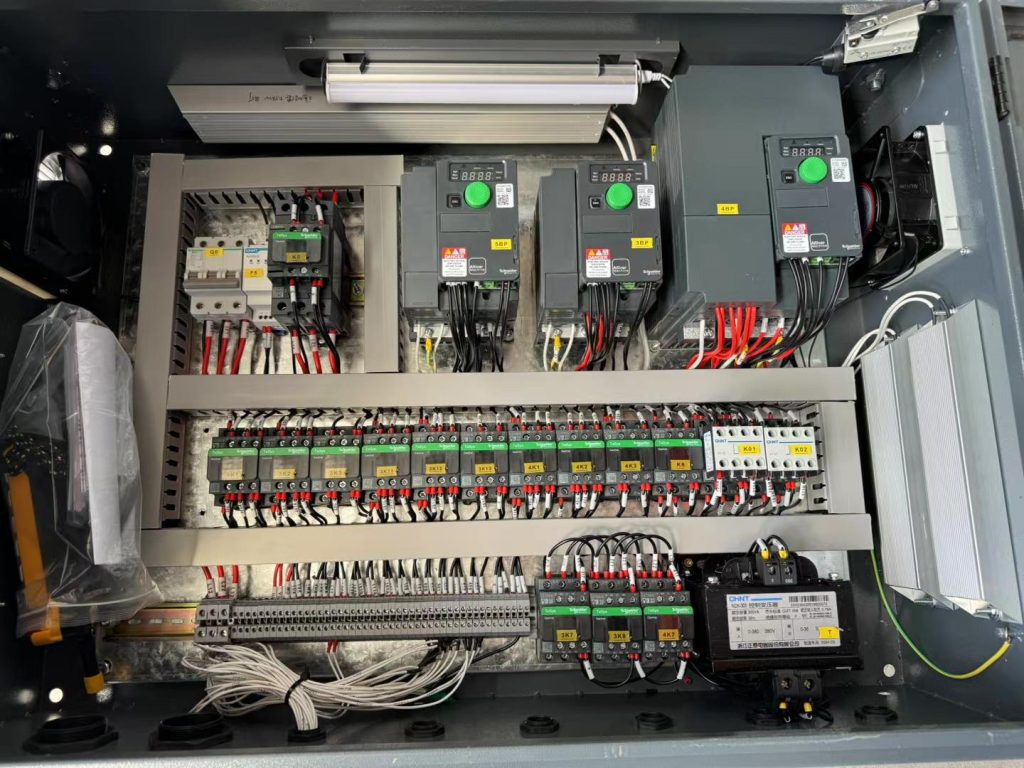

Electrical Systems and Controls

Gantry crane electrical systems deliver power to motors, process control signals from operators, and provide safety monitoring throughout operations. Main power typically feeds through flexible cable reels, festoon systems, or conductor bars depending on travel distances and installation configurations. Motor control methods range from basic contactor systems to sophisticated variable frequency drives enabling precise speed control and soft starting. Additionally, control circuits operate at reduced voltages (24V, 110V) for operator safety while managing relays, contactors, and control logic.

Safety systems represent critical electrical components including overload sensors preventing lifts exceeding rated capacity, limit switches constraining motion within safe boundaries, and emergency stop circuits enabling immediate power disconnection. Modern gantry cranes incorporate programmable logic controllers (PLC) managing complex operational sequences, coordinating multiple motions, and providing diagnostic capabilities. Sensor systems monitor parameters including motor currents, brake temperatures, and operational cycles supporting predictive maintenance programs. These advanced systems prove especially valuable in automated or semi-automated gantry crane installations requiring coordinated operations.

Common Mechanical Faults and Troubleshooting Methods

Wire Rope Degradation and Failure

Common Wire Rope Failure Modes

Wire rope represents one of the most critical gantry crane components requiring constant monitoring and periodic replacement. Common degradation modes include broken wires resulting from fatigue cycles, corrosion from environmental exposure, abrasion from sheave contact, and crushing from improper spooling. These failure modes develop gradually under normal operating conditions. However, overloading, shock loads, or improper handling can accelerate deterioration significantly.

Inspection and Rejection Criteria

Visual inspection protocols specify rejection criteria based on broken wire counts, diameter reduction percentages, and corrosion severity. Industry standards such as ASME B30.2 provide detailed inspection requirements and discard criteria. These standards ensure ropes retire before catastrophic failure risks develop. Inspectors must examine rope condition systematically during regular inspection intervals.

Troubleshooting Wire Rope Problems

Troubleshooting wire rope problems begins with systematic inspection examining entire rope lengths for visible damage. Inspectors should check for bird-caging (wire strand separation), kinking creating permanent deformation, core protrusion indicating internal damage, and localized wear at common contact points. Non-destructive testing using electromagnetic methods detects internal broken wires not visible externally. When inspection reveals damage exceeding acceptance criteria, immediate rope replacement prevents failure risks. Proper rope selection matching duty requirements, correct installation following manufacturer specifications, and adequate lubrication extending service life prove essential preventive measures.

Brake System Malfunctions

Common Brake Problems in Gantry Cranes

Gantry crane brake systems provide critical safety functions including controlled load descent, motion stopping, and load holding during power interruptions. Common brake problems include excessive wear reducing braking force, contamination from oil or debris affecting friction, adjustment drift causing inconsistent performance, and complete failure from component breakdown. These issues compromise safety and require immediate attention when detected.

Symptoms Indicating Brake Issues

Symptoms indicating brake problems include jerky motion during starts or stops, inability to hold loads when power disconnects, excessive stopping distances, and abnormal noises during brake engagement or release. Operators noticing these symptoms should report them immediately. Equipment should be removed from service pending proper diagnosis and repair.

Brake Diagnosis and Repair Procedures

Diagnosis requires inspecting brake pads or shoes for remaining material thickness, contamination presence, and proper clearance adjustment. Worn components exceeding manufacturer discard limits require immediate replacement before complete failure occurs. Spring-set electromagnetic brakes common on gantry cranes should maintain proper air gap between friction surfaces and magnet faces when energized. Incorrect adjustment causes delayed engagement or insufficient holding force. Additionally, inspect brake coils for proper electrical resistance, damaged insulation, or overheating evidence. Establishing regular brake inspection intervals based on duty cycles, promptly addressing identified problems, and maintaining accurate adjustment prevents most brake-related failures.

Gearbox Problems and Solutions

Gearbox failures significantly impact gantry crane availability, often requiring extended downtime for repairs or replacement. Common problems include gear tooth wear or pitting from inadequate lubrication, bearing failures from contamination or lubrication breakdown, seal failures allowing lubricant leakage, and housing cracks from impact loads or fatigue. Early warning signs include abnormal noise levels changing from normal operational sounds, excessive vibration indicating worn bearings or damaged gears, elevated operating temperatures, and visible oil leakage.

Troubleshooting begins with checking lubricant levels ensuring adequate quantity. Next, inspect lubricant condition for contamination or degradation and verify specifications match manufacturer requirements. Oil analysis detects metal particles indicating gear or bearing wear before failure occurs. Vibration analysis using portable analyzers or permanently mounted sensors identifies specific component problems through characteristic frequency patterns. When problems require gearbox disassembly, thorough cleaning and inspection of all components determines which parts require replacement. Preventive measures include following manufacturer lubrication schedules, using correct lubricant types, maintaining proper operating loads, and addressing minor problems before catastrophic damage develops.

Wheel and Rail Wear Issues

Wheel and rail wear represents inevitable consequences of gantry crane operation. However, proper maintenance significantly extends service life. Common wear patterns include flange wear from misalignment forcing lateral contact, tread wear from normal rolling contact, flat spots from emergency braking or excessive slipping, and spalling from surface fatigue. Rail wear manifests as head wear reducing rail height, side wear from wheel flange contact, and corrugation creating rhythmic surface irregularities. Excessive wear causes rough operation, increased power consumption, accelerated component deterioration, and potential derailment risks.

Inspection procedures measure wheel diameter reductions, flange thickness remaining, and tread profile conformance to specifications. Similarly, rail inspections check remaining head height, straightness within tolerance limits, and mounting security. When measurements approach minimum acceptable dimensions, components require machining to restore proper profiles. Complete replacement becomes necessary when insufficient material remains. Alignment verification using precision instruments ensures wheels track properly on rails without excessive skewing generating side forces. Proper lubrication of wheel bearings, maintaining correct rail gauge dimensions, and addressing alignment problems promptly minimize wear rates extending component service life substantially.

Electrical System Faults and Diagnostic Procedures

Motor Failures and Troubleshooting

Electric motor failures represent significant gantry crane problems requiring immediate attention preventing further damage or safety hazards. Common failure modes include winding insulation breakdown from thermal or electrical stress, bearing failures from inadequate lubrication or contamination, shaft damage from misalignment or impact loads, and rotor bar cracks in squirrel cage induction motors. Symptoms indicating developing motor problems include abnormal operating temperatures, unusual noise or vibration, reduced performance, and protection device trips.

Diagnostic procedures begin with basic measurements including motor current draw comparing actual to nameplate values. Insulation resistance testing verifies winding integrity. Vibration analysis identifies mechanical problems. Thermal imaging detects hot spots indicating winding failures, bearing problems, or cooling system obstructions. When motors fail completely, testing determines whether rewinding proves economical or replacement makes better financial sense. Factors influencing this decision include motor age, failure severity, efficiency considerations, and parts availability. Preventive maintenance including periodic lubrication, bearing replacement at appropriate intervals, and maintaining proper ventilation significantly extends motor service life.

Control System and PLC Issues

Modern gantry cranes incorporate sophisticated control systems managing operations, coordinating motions, and providing safety monitoring. Common control problems include input/output module failures preventing proper signal processing, power supply issues affecting system operation, programming errors causing unexpected behaviors, and communication failures between system components. Symptoms range from complete system shutdown to intermittent malfunctions complicating diagnosis.

Troubleshooting control systems requires systematic approaches beginning with verifying power supply voltages at all distribution points. Input signal verification confirms sensors, limit switches, and operator controls function properly and communicate with control systems. Output verification tests ensure control signals reach contactors, motor drives, and other actuated devices. Many PLC systems provide diagnostic displays indicating specific fault conditions or failed components. When problems involve programming, comparing current programs against documented versions identifies unauthorized changes or corruption. Maintaining spare modules for critical components, documenting system configurations, and training maintenance personnel on troubleshooting procedures minimizes downtime when control problems occur.

Festoon and Cable Management Problems

Power and control signal delivery to moving gantry crane components requires specialized cable management systems. Festoon systems suspend cables in loops supported by trolleys traveling with moving equipment. Cable reels wind cables onto spring-loaded drums maintaining proper tension. Common problems include cable damage from excessive flexing, support component failures allowing cable sagging or dragging, collector arm misalignment preventing proper contact, and reel mechanism failures.

Inspection procedures examine cable jackets for cracking, conductor breaks, or connector damage requiring immediate attention. Festoon support systems require checking for damaged trolleys, worn track sections, or misalignment causing binding. Cable reels need periodic inspection verifying spring tension adequacy, slip ring condition, and proper cable spooling without overlapping or gaps. When problems develop, prompt repair prevents cable damage requiring complete replacement. Proper installation following manufacturer specifications, regular inspection programs, and protecting systems from environmental damage extends service life substantially.

Variable Frequency Drive Malfunctions

Variable frequency drives (VFD) controlling modern gantry crane motors provide superior performance but introduce potential failure modes requiring specialized knowledge. Common VFD problems include power component failures from electrical stress or thermal overload, control board failures from environmental contamination, cooling system problems causing overheating, and parameter setting errors affecting performance. Fault codes displayed by VFDs guide troubleshooting. However, interpreting codes requires technical documentation and experience.

Basic troubleshooting verifies input power quality, checks control wiring connections, and confirms parameter settings match application requirements. Advanced diagnosis may require oscilloscope analysis of drive output waveforms, thermal imaging identifying hot components, or component-level troubleshooting. Many VFD manufacturers provide remote diagnostic capabilities enabling expert support during troubleshooting. Preventive maintenance includes maintaining proper ambient temperatures, cleaning cooling air filters, verifying electrical connections remain tight, and protecting drives from environmental contamination. Additionally, maintaining programming backups enables rapid restoration after drive replacement.

Structural Problems and Inspection Techniques

Crack Detection and Weld Failure

Structural cracks represent serious gantry crane problems potentially leading to catastrophic failure if undetected. Cracks typically initiate at stress concentration points including weld toes, structural transitions, bolt holes, and areas experiencing cyclic loading. Factors contributing to crack development include design inadequacies, material defects, fabrication flaws, fatigue from repeated loading, and overload events exceeding design limits. Visual inspection during regular maintenance identifies some cracks. However, non-destructive testing proves necessary detecting subsurface defects.

Inspection methods include magnetic particle testing revealing surface and near-surface cracks in ferromagnetic materials. Liquid penetrant testing suits non-magnetic materials. Ultrasonic testing detects internal defects. Radiographic examination provides permanent records of structural integrity. Inspection frequency depends on duty classification, operating environment, and structural design. Critical areas require more frequent examination. When cracks are detected, qualified welding engineers should evaluate severity. They determine whether repairs prove adequate or component replacement becomes necessary. Repair procedures must follow recognized welding codes ensuring repairs restore structural integrity without introducing new problems.

Structural Deformation and Misalignment

Gantry crane structures experience deformation from various causes including overloading, impact events, improper operation, or gradual changes from repeated stress cycles. Common deformations include bridge beam deflection or twist, leg bending or leaning, and connection distortion. These structural changes cause operational problems including rough travel, binding motions, uneven load distribution, and accelerated component wear. Severe deformation creates safety hazards requiring immediate corrective action.

Detection requires precision measurements comparing actual dimensions against design specifications. Tools include optical levels checking bridge beam alignment, plumb bobs or laser systems verifying leg verticality, and precision measuring instruments checking structural dimensions. When measurements reveal deformation exceeding acceptable limits, structural engineers should evaluate implications. They determine whether operation can continue safely or immediate repairs prove necessary. Correction methods depend on deformation type and severity. Methods range from controlled heating and straightening to reinforcement installation or complete member replacement. Regular measurement programs detect developing deformation enabling corrective action before problems become severe.

Connection and Fastener Problems

Bolted connections throughout gantry crane structures require proper installation and periodic inspection ensuring continued integrity. Common problems include bolt loosening from vibration, thread damage from corrosion or overtorquing, and fastener failure from fatigue or overload. Loose connections create excessive movement causing structural damage, noise, and potential safety hazards. Critical connections such as wheel mounting bolts, structural splice bolts, and equipment attachment fasteners require particular attention during inspections.

Inspection procedures verify all fasteners remain properly tightened using calibrated torque wrenches or appropriate tension indicating methods. Visual inspection identifies damaged threads, corroded components, and missing fasteners requiring replacement. High-strength structural bolts require specific installation procedures including proper tightening sequences and verification methods. When problems are detected, addressing them immediately prevents secondary damage to connected components. Preventive measures include using appropriate locking devices on critical fasteners, following proper installation procedures, and establishing regular inspection schedules based on duty cycles and environmental conditions.

Corrosion Assessment and Protection

Outdoor gantry cranes face continuous corrosion challenges from weather exposure, chemical atmospheres, or marine environments. Corrosion reduces structural section thickness, creates stress concentration points, and produces sharp edges presenting safety hazards. Critical areas requiring attention include structural joints where moisture accumulates, areas with damaged protective coatings, and locations experiencing spray from operations or environmental sources. Left unchecked, corrosion significantly reduces structural capacity and service life.

Assessment procedures include visual inspection identifying rust accumulation and coating degradation. Thickness measurements using ultrasonic equipment detect material loss. Structural evaluation determines whether remaining sections provide adequate strength. When corrosion damage exceeds acceptable limits, repairs may involve removing corroded material and welding replacement sections, reinforcing weakened areas, or replacing severely damaged components. Corrosion prevention strategies include proper surface preparation and coating application, maintaining coating integrity through regular inspection and repair, cathodic protection systems in severe environments, and design modifications eliminating moisture traps where practical.

Preventive Maintenance Programs for Gantry Cranes

Daily and Pre-Shift Inspection Procedures

Daily inspections by operators before each shift represent the first defense against gantry crane problems. These brief examinations identify obvious problems requiring attention before operations commence. Inspection checklists should include verifying all control functions operate properly, checking wire rope condition for visible damage, confirming brakes hold loads and stop motion appropriately, and listening for unusual noises during test movements. Additionally, operators should verify limit switches function correctly, examine hooks and lifting attachments for damage, and ensure adequate lighting and warning devices operate properly.

Documentation proves essential recording inspection findings, problems identified, and corrective actions taken. This historical data tracks equipment condition trends, identifies recurring problems requiring engineering attention, and provides evidence of regulatory compliance. When problems are detected during daily inspections, operators should follow established procedures. They must determine whether equipment remains safe for operation with restrictions, requires immediate repair before use, or must be removed from service pending qualified maintenance personnel evaluation. Clear communication between operators and maintenance departments ensures identified problems receive appropriate priority and resolution.

Weekly and Monthly Maintenance Tasks

Weekly maintenance activities performed by qualified technicians examine components in greater detail than daily operator inspections. Tasks typically include lubricating wheel bearings and other grease points, inspecting wire ropes more thoroughly including hard-to-see sections, checking brake adjustment and operation, verifying electrical connections remain secure, and testing safety devices including overload systems and limit switches. These inspections often identify developing problems before they cause operational failures or safety hazards.

Monthly maintenance expands inspection scope including detailed examination of structural components, motor and gearbox condition assessment, control system verification, and electrical insulation testing. Technicians should measure wheel and rail wear documenting deterioration rates, inspect wire rope more comprehensively possibly including non-destructive testing, verify brake clearances and adjust if necessary, and check all bolted connections ensuring proper tightness. Additionally, reviewing operational records identifies usage patterns, unusual events, or changing performance requiring investigation. Systematic documentation of all maintenance activities creates valuable equipment history supporting informed decisions regarding repairs, component replacement, and eventual equipment retirement or refurbishment.

Periodic Comprehensive Inspections

Annual or semi-annual comprehensive inspections by qualified specialists provide thorough evaluation beyond routine maintenance capabilities. These detailed examinations assess structural integrity through visual and non-destructive testing, evaluate mechanical component condition determining remaining service life, test electrical systems verifying proper function and safety, and conduct load testing demonstrating equipment capacity. Regulatory requirements in most jurisdictions mandate periodic inspections by competent persons. Specific frequencies depend on equipment duty classification and operating conditions.

Comprehensive inspections should include complete wire rope examination possibly requiring removal for detailed assessment. Structural crack detection using appropriate non-destructive methods proves essential. Precise measurement of critical dimensions checks for deformation or wear. Functional testing of all safety systems including emergency stops and overload protection verifies proper operation. Inspection reports document findings, assign priority levels to identified deficiencies, and recommend corrective actions with appropriate timelines. Equipment should not return to service following comprehensive inspections until all critical deficiencies receive correction. Proper documentation demonstrates regulatory compliance.

Lubrication Management Programs

Proper lubrication represents perhaps the most cost-effective maintenance activity extending gantry crane component service life significantly. Comprehensive lubrication programs identify all lubrication points, specify correct lubricant types, establish appropriate intervals, and verify tasks complete properly. Different components require different lubricants. Wheel bearings typically use grease. Open gears may use spray or brush-applied gear compounds. Wire ropes require specialized rope lubricants. Enclosed gearboxes use circulating oils with specific viscosity grades.

Lubrication schedules balance maintenance labor costs against component protection. Critical or high-wear components require more frequent attention. Over-lubrication causes problems including seal damage, contamination attraction, and increased operating temperatures. These issues prove equally problematic as inadequate lubrication. Modern automatic lubrication systems reduce labor requirements while ensuring consistent lubrication intervals. However, they require proper setup and periodic verification of function. Oil analysis programs for gearboxes and hydraulic systems detect contamination, wear particles, and lubricant degradation before component damage occurs enabling proactive maintenance decisions.

Troubleshooting Systematic Approach and Documentation

Developing Effective Diagnostic Procedures

Systematic troubleshooting approaches significantly reduce repair times while preventing misdiagnosis leading to unnecessary parts replacement or recurring failures. Effective procedures begin with gathering information including operator descriptions of problems, identifying when problems occur, determining whether problems developed gradually or suddenly, and reviewing recent maintenance activities potentially related to issues. This information gathering phase prevents wasting time investigating unrelated areas while focusing attention on probable causes.

Diagnostic procedures should follow logical sequences beginning with simple verifications before progressing to complex testing. For example, investigating motor problems should start by confirming power supply presence. Then check control signal integrity and verify basic mechanical freedom before detailed motor testing or disassembly. Utilizing diagnostic tools including multimeters, megohm meters, vibration analyzers, and thermal imaging cameras provides objective data supporting conclusions. When multiple problems exist simultaneously, addressing them systematically prevents confusion. This approach ensures complete problem resolution rather than partial repairs leaving related issues unresolved.

Root Cause Analysis Techniques

Root cause analysis extends beyond immediate problem correction investigating underlying reasons failures occurred. This systematic approach prevents recurring problems by addressing fundamental causes rather than symptoms. Analysis methodologies include “5 Whys” technique repeatedly asking why problems occurred until fundamental causes emerge. Fishbone diagrams organize potential contributing factors into categories. Failure mode effects analysis (FMEA) examines how components fail and consequences thereof.

Effective root cause analysis requires objective evaluation avoiding premature conclusions. Teams should gather factual evidence, interview personnel familiar with equipment, review maintenance histories, and examine failed components carefully. Contributing factors often include multiple elements. These may involve design inadequacies, material defects, improper maintenance, incorrect operation, or environmental conditions. Identifying root causes enables implementing corrective actions preventing recurrence. Actions potentially include design modifications, procedure improvements, enhanced training, or maintenance program adjustments. Documentation of analyses and implemented solutions creates organizational knowledge preventing similar problems on other equipment.

Maintenance Record Keeping Systems

Comprehensive maintenance documentation provides invaluable equipment history supporting informed management decisions. Record systems should capture all maintenance activities. These include routine inspections, lubrication services, adjustments, repairs, component replacements, and comprehensive examinations. Digital maintenance management systems (CMMS) offer advantages over paper records. Benefits include easier data retrieval, trending capability, automated work order generation, and inventory management integration.

Critical information in maintenance records includes specific work performed with sufficient detail enabling future reference. Document parts used with quantities and part numbers. Record labor hours invested, downtime duration, and any unusual findings or conditions noted. Additionally, recording equipment operating hours or cycle counts enables condition-based maintenance scheduling. This approach proves more effective than purely time-based programs. Regular review of maintenance records identifies trends. These may include increasing failure rates suggesting equipment approaching end of useful life, recurring problems indicating inadequate previous repairs, or unusual consumption patterns deserving investigation. These insights support maintenance budget planning, spare parts inventory optimization, and equipment replacement decisions.

Spare Parts Management Strategies

Effective spare parts programs balance carrying costs against downtime risks from parts unavailability. Analysis should identify critical components where failure causes extended downtime, long lead-time items requiring advance procurement, and consumable parts requiring regular replacement. Critical spares for gantry cranes typically include wire ropes, brake components, wheels, bearings, electrical contactors, and control components. Some organizations establish cooperative spare parts agreements with nearby facilities operating similar equipment sharing costs while improving parts availability.

Inventory management systems track parts quantities, locations, costs, and usage patterns. Minimum stock levels prevent depletion before replenishment. Maximum limits prevent excessive capital investment in slow-moving inventory. Regular inventory audits verify physical quantities match records while identifying obsolete items for disposal. For very expensive or rarely used components, establishing supplier relationships guaranteeing rapid delivery may prove more economical than stocking. Additionally, maintaining equipment commonality across facilities simplifies spare parts management through part number standardization and quantity consolidation.

Safety Protocols and Regulatory Compliance

OSHA and ASME Standards for Gantry Cranes

Regulatory compliance represents legal obligations and fundamental safety requirements for gantry crane operations. In the United States, OSHA regulations under 29 CFR 1910.179 establish requirements for overhead and gantry cranes. Requirements include inspection frequencies, operator qualifications, safe operating procedures, and equipment modifications. These regulations reference consensus standards including ASME B30.2 (Overhead and Gantry Cranes) providing detailed technical requirements for design, inspection, testing, maintenance, and operation.

Compliance obligations include conducting frequent inspections before each shift or day of use. Periodic inspections occur monthly or quarterly based on equipment activity. Annual comprehensive examinations by designated persons prove mandatory. Documentation proves essential demonstrating regulatory compliance during workplace inspections. Equipment modifications require engineering evaluation ensuring changes don’t compromise capacity ratings or safety. Additionally, accident investigations must follow established procedures when incidents occur. Organizations should designate qualified persons with documented training and experience overseeing compliance programs ensuring all requirements receive appropriate attention.

Operator Training and Certification

Qualified operators represent critical safety elements in gantry crane operations. OSHA requires operators receive training appropriate to equipment types and operating conditions. Employers remain responsible for evaluating operator competency. Comprehensive training programs combine classroom instruction covering equipment capabilities and limitations, safety procedures, operational controls, and regulatory requirements. Hands-on training develops actual operating skills under supervision.

Training documentation should identify specific content covered, training duration, instructor qualifications, and trainee assessment results. Periodic refresher training maintains competency addressing equipment changes, procedure updates, or performance deficiencies. Some jurisdictions require third-party operator certification. Others allow employer-based programs meeting documented standards. Regardless of specific requirements, ensuring operators understand equipment capacity ratings, proper rigging techniques, hand signal communications, and emergency procedures prevents most operation-related accidents. Additionally, operators should receive instruction on recognizing equipment problems requiring maintenance attention before they develop into serious failures.

Load Testing and Capacity Verification

Load testing validates gantry crane structural capacity and mechanical system adequacy supporting safe operations. Initial load tests before placing new or significantly modified equipment into service verify performance meets design specifications. Testing typically involves lifts to 100% and 125% of rated capacity. During tests, monitor structural deflections, brake holding ability, and overall system performance. Periodic load testing, often required annually or after major repairs, confirms continued capacity compliance.

Test procedures must follow recognized standards ensuring appropriate safety precautions, accurate load measurement, and proper documentation. Testing should occur with experienced supervision, cleared areas preventing personnel exposure to falling load risks, and backup plans addressing potential problems during testing. Documentation includes actual test loads, observed deflections, brake holding verification, and any anomalies noted requiring correction. When equipment fails load testing, thorough investigation determines causes and necessary corrective actions before returning equipment to service. Falsifying load test documentation or operating equipment exceeding rated capacity creates serious liability exposures beyond regulatory violations.

Lockout/Tagout Procedures for Maintenance

Lockout/tagout (LOTO) procedures prevent unexpected equipment energization during maintenance activities. These critical safety protocols require de-energizing equipment, applying locking devices preventing re-energization, and placing tags warning against startup. Comprehensive LOTO programs identify all energy sources. These include electrical power, stored energy in springs or counterweights, and potential gravity-induced motion. Each energy source requires specific isolation methods ensuring complete de-energization before maintenance begins.

Authorized personnel receive training on proper LOTO procedures including equipment-specific requirements, authorized lock types and placement locations, and verification methods ensuring complete de-energization. Group lockout procedures address situations where multiple workers perform maintenance simultaneously. Each worker applies personal locks preventing equipment startup until all workers complete tasks and remove locks. Annual LOTO procedure reviews verify continued adequacy addressing equipment or procedural changes. Documentation requirements include procedure development, personnel training records, and periodic audits confirming compliance. LOTO violations represent serious safety infractions potentially resulting in severe injuries or fatalities deserving organizational emphasis through training, supervision, and enforcement.

Cost-Effective Maintenance and Lifecycle Management

Predictive Maintenance Technologies

Predictive maintenance strategies utilize condition monitoring technologies identifying developing problems before failures occur. Common technologies include vibration analysis detecting bearing wear, gear damage, or shaft misalignment. Thermography identifies hot spots from electrical problems, mechanical friction, or thermal insulation breakdown. Oil analysis reveals contamination, wear particles, or lubricant degradation. These technologies enable condition-based maintenance scheduling replacing components based on actual condition rather than arbitrary time intervals.

Implementation requires initial investment in monitoring equipment and personnel training. However, payback often occurs rapidly through prevented failures and optimized maintenance timing. Vibration monitoring proves particularly effective for rotating equipment including motors, gearboxes, and wheel assemblies. Establishing baseline measurements on new or refurbished equipment provides comparison standards for future readings. Trending data over time reveals deterioration rates enabling planned component replacement during scheduled maintenance rather than emergency repairs. Additionally, predictive technologies optimize maintenance intervals avoiding both premature replacement of serviceable components and delayed replacement risking failures.

Balancing Maintenance Costs and Reliability

Maintenance budget development requires balancing resource investments against acceptable equipment availability and failure risks. Minimal maintenance approaches reduce immediate costs. However, they increase failure rates, unplanned downtime, and emergency repair expenses. These costs often exceed preventive maintenance savings. Conversely, excessive maintenance wastes resources on unnecessary activities providing minimal incremental reliability improvement. Optimal strategies invest in proven preventive activities, utilize predictive technologies on critical components, and maintain appropriate spare parts inventories.

Cost analysis should consider direct maintenance expenses including labor and materials plus indirect costs from production losses during downtime. High-utilization gantry cranes in critical operations justify more intensive maintenance programs than lightly-used equipment. Occasional failures in light-use equipment cause minimal business impact. Benchmarking maintenance costs as percentages of replacement value provides perspective on appropriateness. Typical figures range from 2-6% annually depending on equipment age, duty cycle, and operating environment. Regular review of maintenance effectiveness through metrics including mean time between failures, planned versus unplanned maintenance ratios, and cost per operating hour identifies optimization opportunities.

Equipment Refurbishment vs Replacement Decisions

Aging gantry cranes eventually require major decisions regarding continued operation, comprehensive refurbishment, or complete replacement. Factors influencing these decisions include equipment structural condition, remaining component service life, availability of replacement parts, current capacity adequacy, and comparison of refurbishment costs versus replacement equipment. Structural integrity represents the fundamental consideration. Extensive cracking, severe corrosion, or structural deformation may render refurbishment uneconomical compared to replacement.

Refurbishment projects can include complete mechanical system replacement with modern components, updated electrical controls incorporating current technology, structural reinforcement or repair, and component upgrades improving capacity or performance. Well-executed refurbishments often cost 40-60% of equivalent new equipment while extending service life 15-20 years. However, refurbishment economics depend heavily on equipment structural condition and compatibility with modern components. When equipment utilizes obsolete designs complicating parts sourcing or limiting performance, replacement may prove more economical long-term despite higher initial costs. Professional engineering evaluation provides objective assessment supporting informed decisions considering both technical and financial factors.

Extending Gantry Crane Service Life

Maximizing gantry crane service life delivers excellent return on capital investments while deferring replacement costs. Key strategies include rigorous preventive maintenance programs addressing problems before serious damage develops. Operate equipment within design parameters avoiding overloads and abuse. Protect structures from environmental degradation through proper coatings and corrosion control. Make timely component replacements preventing collateral damage from failed parts.

Environmental protection proves particularly important for outdoor gantry cranes constantly exposed to weather. Maintaining coating integrity through regular inspection and prompt repair prevents corrosion initiation. In aggressive environments such as marine locations or chemical facilities, cathodic protection systems provide additional defense beyond coatings alone. Operational discipline preventing overloads, shock loads from improper operation, and impacts from careless handling preserves structural integrity indefinitely. Additionally, maintaining current documentation including original design specifications, operating manuals, and complete maintenance histories enables informed decision-making throughout equipment lifecycle supporting optimal management strategies.

Frequently Asked Questions

What are the most common gantry crane problems?

The most frequent gantry crane issues include wire rope wear requiring periodic replacement, brake system problems affecting safety, wheel and rail wear from normal operation, electrical control failures, and structural cracks from fatigue. Regular inspection and preventive maintenance significantly reduce these problems. Establishing comprehensive maintenance programs based on equipment duty cycles and operating conditions provides optimal reliability while minimizing unexpected failures and associated costs.

How often should gantry cranes undergo inspection?

Daily pre-shift inspections by operators verify basic safety before each use. Monthly inspections by qualified maintenance personnel examine components in greater detail. Annual comprehensive inspections by certified inspectors satisfy regulatory requirements. Equipment operating in severe duty cycles or harsh environments may require more frequent inspection intervals. Always follow manufacturer recommendations and applicable regulations for specific equipment and jurisdictions.

What causes gantry crane wheels to wear prematurely?

Premature wheel wear typically results from misalignment causing excessive side loading, inadequate lubrication accelerating bearing and tread wear, overloading beyond design capacity, rail problems including gauge variations or surface irregularities, and contamination from abrasive materials. Proper alignment verification, regular lubrication, respecting capacity limits, and maintaining rail systems in good condition significantly extends wheel service life while reducing maintenance costs.

How can I tell if my gantry crane needs immediate repair?

Warning signs requiring immediate attention include unusual noises indicating mechanical problems, jerky or erratic motions, visible structural damage such as cracks or deformation, excessive wire rope wear or broken wires, brake problems preventing proper load control, and any control system malfunctions. When these symptoms appear, equipment should be removed from service immediately. Keep it offline pending qualified inspection and appropriate repairs ensuring safe operation.

What maintenance records should be kept for gantry cranes?

Comprehensive records should document all inspections with findings and corrective actions, maintenance activities including routine servicing and repairs, component replacements with part numbers and dates, load testing results, operator training and certifications, and any modifications or upgrades. These records demonstrate regulatory compliance, track equipment condition trends, support maintenance planning, and provide valuable history during troubleshooting or replacement decisions.

Can I perform my own gantry crane repairs?

Simple maintenance tasks like lubrication and minor adjustments can be performed by trained maintenance personnel. However, major repairs involving structural modifications, welding, load-bearing component replacement, or safety system work require qualified specialists. These specialists need appropriate training, experience, and certifications. Improper repairs create serious safety hazards and liability risks. Always consult equipment manufacturers and qualified engineers for significant repair work ensuring compliance with applicable standards.

Conclusion

Effective gantry crane maintenance requires comprehensive understanding of common faults, systematic troubleshooting approaches, and disciplined preventive maintenance programs. The combination of daily operator inspections, regular maintenance activities, periodic comprehensive examinations, and prompt attention to identified problems maximizes equipment reliability. This approach minimizes unexpected failures and associated costs. Addressing mechanical wear, electrical system problems, and structural deterioration through established procedures prevents most operational disruptions and safety incidents.

Implementing predictive maintenance technologies, maintaining detailed equipment records, and developing qualified maintenance personnel creates sustainable reliability programs supporting long-term operational success. Organizations should view gantry crane maintenance as strategic investments rather than discretionary expenses. Proper maintenance delivers excellent returns through extended equipment life, reduced downtime, improved safety, and optimized operational performance. Whether managing single installations or complex equipment fleets, these fundamental principles guide effective maintenance program development.

Regular training updates for operators and maintenance personnel, staying current with regulatory requirements, and learning from industry best practices ensure programs remain effective as equipment ages and technology evolves. Partnering with equipment manufacturers, consulting experienced engineers when needed, and investing in appropriate diagnostic tools further enhances maintenance capability. Through disciplined application of proven maintenance principles and continuous improvement initiatives, organizations achieve optimal gantry crane reliability. This supports manufacturing productivity, operational safety, and long-term cost-effectiveness throughout equipment service lives.

Safety Disclaimer: This article provides general guidance only. All gantry crane inspection, maintenance, repair, and operation must be performed by qualified professionals following applicable safety standards and regulations. Consult certified engineers, comply with OSHA requirements, follow ASME standards, and adhere to manufacturer specifications before proceeding with any maintenance or repair activities.

Technical Specification Disclaimer: Equipment specifications, maintenance requirements, and repair procedures vary by manufacturer, model, age, and application. Always refer to manufacturer documentation and consult professional engineers for project-specific requirements. Information presented reflects general industry practices and should be verified for specific circumstances and local regulatory requirements.

Need Expert Gantry Crane Maintenance Support? Contact qualified crane service professionals for technical consultation, comprehensive inspections, preventive maintenance programs, and emergency repair services tailored to your specific gantry crane equipment and operational requirements.

Professional Gantry Crane Services – Inspection, Maintenance & Repair Solutions