Looking for an Overhead Crane in Thailand? A Guide to CATET CRANE’S Industrial Solutions

Thailand’s manufacturing and logistics sectors continue expanding rapidly, creating increasing demand for reliable material handling equipment. Industrial facility managers throughout Bangkok, Rayong, and Chonburi face challenges sourcing quality overhead cranes with responsive technical support and reasonable delivery times. CATET CRANE, a leading overhead crane Thailand supplier and subsidiary of China’s Dongqi Group established in 2006, offers comprehensive industrial lifting solutions with proven international experience across 90+ countries. This guide explores how CATET CRANE’s product range addresses diverse material handling requirements while providing the technical expertise and service support Thai industries need for successful equipment implementation.

Understanding CATET CRANE: Your Overhead Crane Thailand Supplier

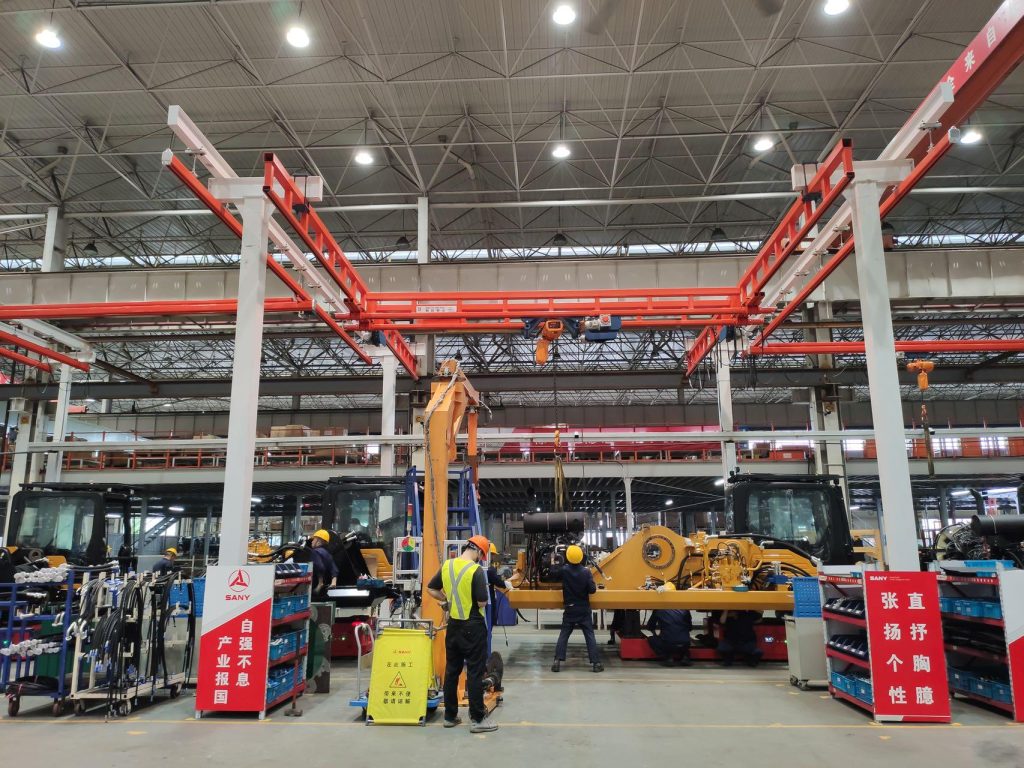

CATET Co., Ltd. operates as a specialized overhead crane Thailand manufacturer under Dongqi Group’s umbrella. Founded in 2006, the company has developed extensive manufacturing capabilities supported by modern production facilities and advanced R&D capabilities. Furthermore, CATET maintains multiple international certifications including ISO 9001, ISO 14001, ISO 50001, and EU CE certification, demonstrating commitment to quality management and product safety standards.

The company’s product portfolio encompasses bridge cranes, gantry cranes, electric hoists, KBK crane systems, jib cranes, electric transfer carts, and specialized lifting equipment. These solutions serve diverse industries including steel production, power generation, petrochemicals, logistics operations, and automotive manufacturing. With products exported to over 90 countries globally, CATET has accumulated substantial international project experience applicable to Thailand’s industrial requirements.

CATET’s manufacturing approach emphasizes precision and quality control. Production facilities incorporate laser cutting technology, coordinate measurement systems, and rigorous quality verification processes. Each crane undergoes comprehensive testing before shipment, ensuring equipment meets specified performance standards. Additionally, the company offers 12-month warranty coverage on delivered equipment, providing customers with quality assurance during initial operational periods.

The company’s headquarters location in Shenzhen, China, positions CATET for efficient export operations to Southeast Asian markets including Thailand. Standard delivery timeframes range from 20-30 days for conventional models, while customized solutions typically require 30-60 days depending on project specifications. These timelines compare favorably with many international suppliers while offering cost advantages through regional proximity.

Comprehensive Overhead Crane Thailand Product Range

Single Girder Overhead Crane Thailand Solutions

CATET manufactures various single girder overhead crane Thailand configurations suitable for light to medium-duty applications. The LD A3 series represents standard single-girder designs incorporating electric hoists for lifting operations. These systems provide economical solutions for workshops, warehouses, and production facilities requiring reliable material handling capabilities without extensive structural modifications.

Single girder designs offer several practical advantages. The simplified structure reduces building load requirements compared to double girder alternatives, potentially lowering facility construction or modification costs. Additionally, compact configurations work well in spaces with limited overhead clearance. Standard capacity ranges extend up to 20 tons, accommodating typical manufacturing and logistics handling needs.

The MATE-LD-M5 series represents CATET’s enhanced single-girder offering, incorporating modern design features and improved performance characteristics. These systems utilize advanced control technologies enabling smooth operation and precise load positioning. Variable frequency drives provide gradual acceleration and deceleration, reducing mechanical stress and extending component service life. Moreover, wireless remote controls enhance operator convenience and safety.

Electric wire rope hoists integrated with single girder cranes offer various capacity options from 1 ton to 20 tons. CATET provides both CD/MD standard hoists and European-standard wire rope hoists, allowing customers to select appropriate specifications based on performance requirements and budget considerations. European-standard variants typically incorporate enhanced features including improved duty ratings and refined control characteristics.

Double Girder Overhead Crane Thailand Systems

For heavier lifting requirements, CATET offers double girder overhead crane Thailand systems including the LH A3 and QD A5-A7 series. The dual girder construction provides superior rigidity and load capacity, enabling operations from 20 tons up to 100+ tons depending on configuration. These robust systems suit demanding applications in steel mills, heavy equipment manufacturing, shipyards, and large-scale logistics operations.

The LH A3 double-girder overhead crane represents CATET’s standard heavy-duty offering for general industrial applications. This series incorporates reliable mechanical designs proven across numerous installations worldwide. Structural components undergo precision fabrication and quality verification, ensuring long-term operational reliability. Standard features include overload protection, limit switches, and emergency stop functionality meeting international safety requirements.

QD A5-A7 series cranes address more intensive duty requirements where frequent operation and heavier loads demand enhanced durability. The A5-A7 working level classification indicates suitability for regular daily use with moderate to heavy utilization patterns. These systems incorporate reinforced structural elements, higher-grade components, and improved bearing specifications compared to A3 classification equipment.

Double girder configurations accommodate larger lifting heights and wider spans than single girder alternatives. Maximum spans can exceed 30 meters, while lifting heights extend beyond 20 meters depending on specific project requirements. This versatility makes double girder cranes essential for facilities handling large machinery, steel products, containers, or other oversized materials requiring substantial vertical and horizontal movement capabilities.

Complementary Lifting Equipment Solutions

Gantry Crane Systems

CATET’s product line includes both single and double girder gantry cranes for outdoor applications or facilities lacking overhead runway structures. Portable gantry cranes offer flexibility for maintenance operations, equipment installation projects, or temporary lifting needs. These mobile systems feature adjustable heights and spans, adapting to various work scenarios without permanent installation requirements.

Fixed gantry cranes provide stable heavy lifting capabilities for shipyards, rail yards, container terminals, and steel stockyards. The dual-leg structure supports heavy loads while enabling travel along ground-level rails. Configurations range from simple A-frame designs to complex double-trolley systems capable of coordinated lifting operations. Weather-resistant construction ensures reliable outdoor performance in tropical climates.

KBK Modular Crane Systems

KBK (Kombinierter Bahnkranbau) crane systems offer flexible solutions for assembly lines, manufacturing cells, and workstation lifting needs. The modular aluminum or steel track system enables custom layouts following production flow requirements. Lightweight construction facilitates installation while maintaining adequate load capacity for typical workshop handling operations.

These systems excel in applications requiring frequent load movement along defined paths. Manufacturing assembly operations benefit from KBK systems providing workers with ergonomic load handling capabilities reducing manual effort and injury risks. Furthermore, the modular nature allows system expansion or reconfiguration as production requirements evolve, protecting equipment investment value.

Jib Crane Options

CATET manufactures wall-mounted and column-mounted jib cranes for localized lifting needs. These compact systems provide economical solutions for workstations, loading docks, and machine tool tending applications. Rotation capabilities typically span 180-270 degrees, covering semicircular or three-quarter work areas. Capacity ranges extend from 0.5 to 10 tons, addressing diverse light to medium-duty requirements.

Wall-mounted jib cranes offer space-saving advantages by utilizing building columns or walls as primary support structures. Installation requires adequate wall strength and proper anchor design to safely transfer operational loads. Column-mounted alternatives provide standalone installations when suitable wall structures are unavailable, though requiring floor foundation work.

Electric Transfer Cart Solutions

Electric flat cars and transfer carts complement crane systems for ground-level material transport. Rail-guided versions follow fixed pathways suitable for repetitive transfer operations between production areas or storage locations. Trackless alternatives utilize battery power and steering systems, providing flexible movement similar to forklifts but with higher capacity and specialized features.

These transport solutions prove particularly valuable in operations requiring coordinated crane and horizontal transport movements. For example, overhead cranes load materials onto transfer carts which then convey loads to distant processing stations or storage areas. This integrated approach optimizes overall material flow efficiency while reducing manual handling and forklift traffic.

Overhead Crane Thailand: Technical Specifications and Customization

CATET provides overhead crane Thailand customization services tailoring equipment to specific project requirements. Engineers evaluate customer lifting needs, facility dimensions, operational patterns, and environmental conditions to develop optimized solutions. This consultation process ensures selected equipment matches actual application demands rather than forcing customers into standardized products potentially unsuitable for their circumstances.

Technical specifications vary considerably across product ranges. Single girder overhead cranes typically offer lifting speeds of 1-8 m/min and travel speeds of 20-30 m/min. Double girder systems may provide enhanced speed characteristics depending on application requirements. Working duty classifications from A3 (light intermittent use) through A7 (heavy frequent use) address different operational intensity levels.

Power supply options accommodate various facility electrical systems. Standard configurations operate on three-phase AC power at common industrial voltages. Control systems range from basic pendant controls to wireless radio remotes providing operators with flexible positioning options. Advanced features such as variable frequency drives, anti-sway systems, and programmable logic controllers are available for applications demanding enhanced performance or automation integration.

Environmental adaptations address specific operating conditions. Outdoor cranes require weather protection including sealed electrical components, corrosion-resistant coatings, and special lubricants for tropical climates. Indoor cleanroom applications may need stainless steel construction and sealed designs preventing contamination. CATET’s engineering team evaluates these requirements during project planning to incorporate necessary features.

Quality Certifications and Manufacturing Standards

CATET’s manufacturing operations maintain multiple quality management certifications demonstrating systematic approaches to product quality and consistency. ISO 9001 certification validates quality management systems governing design, production, and service activities. This internationally recognized standard ensures documented processes, regular audits, and continuous improvement methodologies drive operational excellence.

Environmental management certification under ISO 14001 reflects CATET’s commitment to minimizing manufacturing environmental impacts. These systems govern waste management, resource utilization, and pollution prevention activities throughout production operations. Similarly, ISO 50001 energy management certification addresses energy efficiency and consumption reduction initiatives.

EU CE marking on CATET products indicates conformity with European health, safety, and environmental protection standards. This certification requires comprehensive technical documentation, risk assessment, and third-party verification processes. While not mandatory for Thai market entry, CE marking demonstrates product quality and safety design meeting stringent international requirements that often exceed minimum local standards.

The company maintains numerous utility model patents covering various crane and material handling equipment innovations. These patents reflect ongoing investment in research and development activities aimed at improving product performance, safety features, and operational efficiency. Patent portfolio development demonstrates technical capability and commitment to innovation rather than simply copying existing designs.

Installation and Commissioning Support Services

CATET provides technical guidance supporting equipment installation and commissioning activities. While the company primarily supplies equipment rather than performing on-site installation work in Thailand, their engineering team offers comprehensive documentation, remote technical consultation, and troubleshooting assistance ensuring successful project implementation by local contractors or customer maintenance teams.

Installation manuals include detailed assembly instructions, component identification, connection diagrams, and quality verification procedures. These documents enable qualified local technicians or contractors to properly install supplied equipment following manufacturer specifications. Additionally, electrical schematics and wiring diagrams support electricians during control system installation and connection work.

Pre-shipment testing documentation provides baseline performance data for installed equipment. Load test certificates verify structural capacity and safety systems functionality before shipping. Customers can reference this documentation during commissioning to confirm proper installation and operation. Any discrepancies between factory testing and site performance indicate potential installation issues requiring correction.

Remote technical support via phone, email, or video conferencing helps address questions arising during installation and initial operation phases. CATET’s engineering team can review photographs, discuss observed behaviors, and recommend corrective actions for most common issues. This support proves valuable when local contractors encounter unfamiliar situations or need clarification regarding technical specifications.

Maintenance Recommendations and Spare Parts Availability

Proper maintenance practices significantly impact crane equipment longevity and reliability. CATET provides maintenance guidance documentation outlining recommended inspection schedules, lubrication requirements, and wear component monitoring procedures. Following these guidelines helps prevent premature failures and maintains safe operating conditions throughout equipment service life.

Regular inspection routines should examine critical components including wire ropes, brakes, limit switches, electrical connections, and structural elements for wear, damage, or deterioration. Monthly inspections performed by trained maintenance personnel identify developing problems before failures occur. Annual comprehensive examinations by qualified inspectors satisfy regulatory requirements while providing thorough equipment condition assessment.

Lubrication maintenance proves essential for moving components including bearings, gears, and wire rope. Using appropriate lubricants at specified intervals prevents accelerated wear and maintains smooth operation. Tropical environments may require more frequent lubrication attention due to higher ambient temperatures and humidity levels affecting lubricant performance and longevity.

Spare parts procurement represents an important operational consideration when sourcing equipment from international suppliers. CATET maintains spare parts inventory for supplied equipment, though delivery times to Thailand require consideration. Customers should maintain critical spare parts inventory for components requiring frequent replacement or those with longer lead times. Common wear items such as brake pads, limit switches, electrical contactors, and wire rope merit local stock consideration.

Overhead Crane Thailand Applications Across Industrial Sectors

Overhead Crane Thailand for Manufacturing Industry

Thailand’s extensive manufacturing sector presents diverse overhead crane Thailand equipment requirements. Automotive component production facilities utilize overhead cranes for machining operations, assembly processes, and parts warehousing. Single girder cranes between 3-10 tons capacity suit most automotive parts handling needs, while heavier press equipment or vehicle body handling may require double girder systems.

Electronics manufacturing operations often need precise load positioning capabilities and contamination-free designs. Clean working environments benefit from sealed electrical components and smooth operation minimizing particle generation. KBK crane systems provide flexible solutions for electronics assembly workstations requiring frequent load repositioning within defined work areas.

Food processing and beverage production facilities require sanitary designs using stainless steel construction or protective coatings preventing corrosion in washdown environments. Overhead cranes handle packaged products, process equipment, and bulk ingredient containers. Moderate capacity requirements typically favor single girder configurations offering economical solutions for these applications.

Overhead Crane Thailand for Logistics and Warehousing

Modern distribution centers requiring overhead crane Thailand solutions throughout Bangkok and eastern seaboard industrial zones utilize crane systems for container handling, palletized goods movement, and high-bay storage operations. Gantry cranes prove particularly suitable for outdoor container yards and intermodal transfer facilities. Indoor warehouses benefit from overhead crane systems maximizing floor space utilization without ground-level obstructions.

Double girder overhead cranes with 20-50 ton capacity address container handling requirements in ports and inland container depots. Specialized spreader attachments enable secure container lifting and precise positioning during loading and unloading operations. High-speed configurations maximize throughput in busy logistics operations where equipment cycle time directly impacts facility capacity.

Construction and Heavy Industry

Steel fabrication facilities, shipyards, and heavy equipment manufacturers require robust crane systems handling large structural components, heavy machinery, and assembled products. Double girder cranes rated from 30 tons up to 100+ tons provide necessary capacity for these demanding applications. Outdoor installations require weather-resistant construction withstanding tropical climate conditions including high temperatures, humidity, and seasonal monsoons.

Project-based industries benefit from portable gantry cranes supporting maintenance operations, equipment installation projects, or temporary lifting needs at construction sites. These mobile systems eliminate permanent installation requirements while providing reliable lifting capabilities. Adjustable configurations accommodate varying work scenarios encountered across different project phases or locations.

Comparing International vs. Regional Suppliers

When evaluating overhead crane Thailand equipment sources, Thai companies must consider various factors beyond initial purchase price. International suppliers from China, Europe, or other regions each present distinct advantages and limitations affecting total project costs and long-term operational experience. Understanding these differences helps inform appropriate sourcing decisions based on specific project circumstances and company priorities.

Delivery timeframes significantly impact project schedules and business planning. CATET’s regional proximity enables relatively rapid shipping to Thailand compared to European manufacturers requiring extended ocean transport. Standard lead times of 20-30 days for conventional equipment compare favorably with many alternatives. However, custom specifications extending manufacturing periods still require 30-60 days before shipping.

Initial equipment costs from Chinese manufacturers like CATET generally offer advantages compared to European alternatives, though quality specifications and feature content vary considerably. Customers must carefully evaluate whether lower-priced options provide adequate performance, reliability, and service life for their applications. Sometimes paying premium prices for enhanced quality proves economical through reduced maintenance costs and extended operational life.

Technical support responsiveness varies considerably between different suppliers. Local representation, language capabilities, time zone alignment, and cultural familiarity all influence effective communication during installation, operation, and maintenance phases. Chinese suppliers serving Thai markets typically provide English language support and understand regional business practices, though direct Thai language capabilities may be limited compared to local dealers.

Project Planning and Procurement Considerations

Successful overhead crane Thailand projects require thorough planning addressing technical, logistical, and commercial aspects. Initial planning should define specific lifting requirements including maximum loads, lifting heights, span dimensions, and duty cycle expectations. These fundamental specifications drive equipment selection and determine appropriate crane classifications and features.

Facility structural assessment proves critical before finalizing equipment specifications. Overhead cranes impose significant loads on building structures through runway beam reactions. Existing facilities may require structural reinforcements to safely support planned crane systems. Early structural engineering consultation prevents discovering inadequate capacity after ordering equipment, avoiding costly delays and modifications.

Budget development should account for complete project costs including equipment purchase price, shipping and import duties, installation labor and materials, electrical work, runway structure construction or modification, operator training, and initial spare parts procurement. Focusing solely on equipment price overlooks substantial additional costs that may dramatically affect total project investment requirements.

Vendor evaluation criteria should extend beyond price comparisons to assess quality certifications, manufacturing capabilities, delivery reliability, technical support quality, warranty terms, and spare parts availability. Checking references from previous customers in similar industries provides valuable insights into actual supplier performance and product quality experienced during long-term operation.

Understanding Warranty Coverage and After-Sales Support

CATET provides 12-month warranty coverage on delivered equipment from commissioning date. This warranty addresses manufacturing defects and component failures resulting from materials or workmanship issues. However, customers should carefully review warranty terms understanding covered components, excluded items, claim procedures, and any maintenance requirements affecting warranty validity.

Warranty coverage typically excludes wear components subject to normal operational consumption such as brake pads, wire rope, contact tips, and similar items expected to require periodic replacement. Additionally, damage from improper operation, inadequate maintenance, unauthorized modifications, or accidents generally falls outside warranty scope. Understanding these limitations helps set realistic expectations and plan for operational expenses.

Making warranty claims with international suppliers requires proper documentation and communication. Customers should maintain detailed operation and maintenance records supporting any claims. Photographic evidence, component identification information, and clear problem descriptions facilitate efficient claim processing. However, geographic distance and shipping logistics may complicate warranty parts replacement compared to locally-supported equipment.

After-sales technical support availability represents an important consideration when sourcing equipment internationally. CATET offers remote technical assistance via phone and email during normal business hours. While this support proves valuable for troubleshooting and technical questions, on-site service visits to Thailand require special arrangements and involve additional costs and scheduling lead time.

Safety Standards and Regulatory Compliance

Crane equipment operating in Thailand must comply with applicable safety regulations and industry standards. The Thai Department of Labour Protection and Welfare establishes requirements governing industrial equipment including periodic inspections, operator certification, and safe operating procedures. Facility managers should verify compliance requirements with local authorities when planning crane installations.

International standards such as ISO, FEM, and DIN provide technical specifications for crane design, manufacturing, testing, and operation. CATET designs products following these international standards, which often exceed minimum local requirements. Equipment meeting rigorous international standards generally provides enhanced safety performance compared to products manufactured without such oversight.

Operator training proves essential for safe crane operation. Untrained personnel lack understanding of load capacity limits, proper operating procedures, and hazard recognition necessary for safe equipment use. Training programs should cover pre-operation inspections, load weight estimation, safe lifting practices, hand signal communication, and emergency response procedures. Documented training records demonstrate compliance efforts and support insurance requirements.

Regular equipment inspections by qualified personnel satisfy regulatory requirements while identifying potential safety hazards before accidents occur. These inspections should examine structural components, mechanical systems, electrical systems, and safety devices for proper condition and functionality. Any deficiencies require immediate correction before returning equipment to service. Maintaining detailed inspection records documents compliance and equipment condition history.

Making Informed Crane Equipment Decisions

Selecting appropriate overhead crane Thailand equipment requires balancing multiple factors including technical capability, quality, cost, delivery timing, and support services. No single supplier or product represents the optimal choice for all situations. Rather, specific project circumstances, company priorities, and operational requirements determine which options best suit particular needs.

Companies prioritizing lowest initial costs may find Chinese manufacturers like CATET offering attractive value propositions. However, customers should realistically assess quality levels, expected service life, and support capabilities ensuring selected equipment adequately serves intended applications. Sometimes modest price increases for enhanced quality grades or features provide better long-term value through reduced maintenance and longer operational life.

Organizations emphasizing maximum reliability or specialized requirements might justify premium pricing for European manufacturers despite higher costs. These suppliers typically offer enhanced engineering support, proven reliability track records, and comprehensive service networks supporting global operations. The cost premium may prove worthwhile for mission-critical applications where equipment downtime causes severe business impact.

Working with experienced local distributors or engineering firms can provide valuable guidance navigating equipment selection, import logistics, installation coordination, and regulatory compliance. These partners understand Thai market conditions, business practices, and technical requirements while offering ongoing support proximity after equipment commissioning. Their services add value justifying reasonable markup over direct importing.

Frequently Asked Questions

What overhead crane Thailand capacity do I need for my application?

Capacity selection should exceed maximum anticipated loads by appropriate safety margins, typically 25-50% depending on load uncertainty and operational conditions. Consider not only primary load weights but also lifting attachment weights, dynamic effects during acceleration, and potential future requirement increases. Consulting with experienced crane engineers helps determine appropriate specifications.

How long does equipment delivery to Thailand typically require?

Standard CATET crane models generally ship within 20-30 days from order confirmation, with ocean freight to Thailand requiring approximately 2-3 weeks additional time. Custom configurations may extend manufacturing periods to 30-60 days. Total project timelines should also account for import clearance procedures, inland transportation, and installation work.

Can CATET provide installation services in Thailand?

CATET primarily supplies equipment rather than performing direct installation work internationally. However, they provide comprehensive installation documentation and remote technical support enabling qualified local contractors to properly install equipment. Some customers arrange installation through local crane service companies familiar with similar equipment.

What maintenance support is available after purchase?

CATET offers remote technical support for troubleshooting and maintenance guidance via phone and email. Spare parts can be ordered and shipped from China, though delivery times require consideration. Customers should identify qualified local maintenance contractors familiar with industrial crane equipment for routine service work and repairs.

How does pricing compare to other crane suppliers?

CATET’s pricing generally positions competitively within the Chinese crane manufacturer segment, typically lower than European suppliers but varying based on specific configurations and features. Total project cost comparisons should account for shipping, duties, installation, and long-term operational expenses rather than focusing solely on equipment purchase price.

What certifications does CATET equipment carry?

CATET maintains ISO 9001, ISO 14001, ISO 50001, and EU CE certifications. Equipment designs follow international standards including FEM and ISO crane specifications. Customers should verify that selected products carry appropriate certifications meeting their specific requirements and local regulatory standards.

Conclusion

CATET CRANE offers overhead crane Thailand and industrial lifting solutions addressing diverse material handling requirements across manufacturing, logistics, construction, and other sectors. As a subsidiary of Dongqi Group with nearly two decades of experience and exports to over 90 countries, the company brings established manufacturing capabilities and international project experience to equipment sourcing considerations.

The product portfolio spanning single and double girder overhead cranes, gantry cranes, KBK systems, jib cranes, electric hoists, and transfer carts provides options suitable for varied applications and capacity requirements. Quality certifications including ISO 9001 and CE marking demonstrate systematic manufacturing approaches and conformity with international standards. Standard delivery timeframes of 20-60 days depending on customization level position CATET competitively for project planning purposes.

Companies evaluating crane equipment options should carefully assess technical requirements, quality expectations, budget constraints, support needs, and total cost considerations determining which supplier best aligns with their specific circumstances. CATET represents one viable option among various international and regional suppliers serving Thai markets, each offering distinct advantages depending on particular project priorities and operational contexts.

Safety Disclaimer: This article provides general information only. All crane selection, installation, operation, and maintenance must be performed by qualified professionals following applicable safety standards and regulations. Consult certified engineers and comply with Thai regulatory requirements before proceeding.

Technical Specification Disclaimer: Equipment specifications, parameters, and capabilities may vary by model and application. Always refer to manufacturer documentation and consult qualified engineers for project-specific requirements. Information presented reflects company-provided data and should be independently verified for accuracy.

Need Expert Crane Equipment Guidance? Contact CATET CRANE for technical consultation and equipment quotations tailored to your specific material handling requirements.

Contact Information:

- Email: [email protected]

- WhatsApp: +86 159 9309 7180

- Phone: +86 159 9309 7180