What Are KBK Cranes? Complete Guide to Modular Workstation Lifting Systems and Their Industrial Applications

Introduction: Understanding KBK Crane Technology

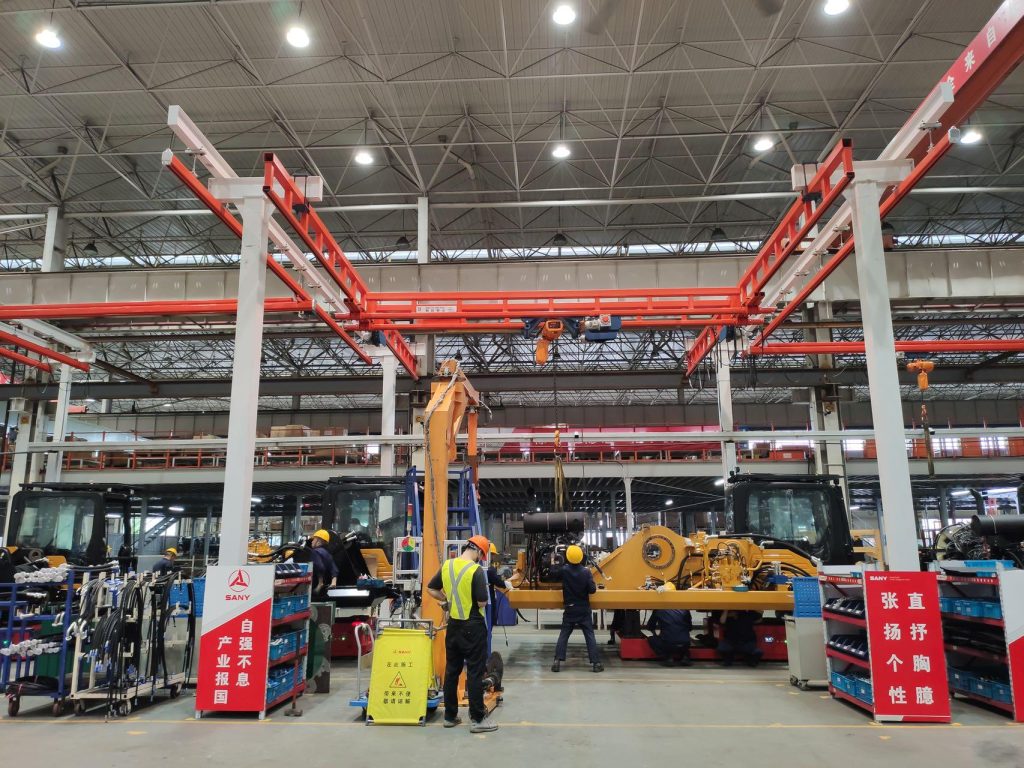

KBK cranes represent a revolutionary category of modular workstation lifting systems designed to optimize material handling in assembly lines, manufacturing facilities, and clean room environments. The acronym “KBK” originates from the German “Kombiniertes Brückenkransystem,” which translates to “combined bridge crane system.” Alternatively known as flexible beam cranes, these innovative enclosed track systems utilize standardized modular components that can be configured into customized lifting solutions ranging from simple monorails to complex multi-axis workstation systems.

First introduced over 50 years ago by Demag, KBK systems have become the world market leader in modular crane technology. Moreover, the flexible design allows organizations to create precise material handling solutions matching specific operational requirements. Unlike traditional overhead bridge cranes requiring substantial building modifications, KBK cranes integrate seamlessly into existing infrastructure with minimal structural impact. Specifically, the maximum lifting capacity reaches 2,000 kilograms (2 tons), making them ideal for light to medium-duty applications across diverse industrial sectors.

The modular nature of KBK cranes delivers exceptional adaptability throughout equipment service life. Consequently, facilities can modify, expand, or reconfigure systems as production needs evolve without replacing entire installations. This flexibility, combined with smooth operation, ergonomic design, and space-efficient profiles, explains why KBK technology dominates modern manufacturing environments requiring precision material handling capabilities.

Core Components and Design Architecture of KBK Cranes

Essential System Components

KBK crane systems comprise seven fundamental components working together to create flexible material handling solutions. The suspension device anchors the entire system to building structures, distributing loads safely throughout the support framework. Specifically, adjustable mounting brackets accommodate varying installation conditions while maintaining critical alignment tolerances.

Track rails form the foundation guiding trolleys and hoists along predetermined paths. These enclosed profiles protect internal rolling surfaces from contamination. The counterweight system balances loads during operation, reducing motor requirements and improving energy efficiency. Furthermore, the trolley assembly carries loads along track paths, equipped with precision bearings ensuring smooth, low-friction movement.

Electric chain hoists provide vertical lifting capability, available in capacities from 125 kilograms to 2,000 kilograms. Mobile power supply devices, commonly called festoon systems or conductor bars, deliver electrical power to moving components throughout the working envelope. Finally, control units enable operator commands through pendant controls, radio remotes, or automated programmable systems.KBK track systems utilize cold-rolled steel profiles meeting ASTM standards or aluminum profiles engineered for optimal strength-to-weight ratios. Steel profiles deliver maximum rigidity suitable for longer spans and heavier loads up to 2,000 kilograms. In contrast, aluminum track options provide lightweight solutions reducing dead weight while maintaining adequate strength for loads up to 2,000 kilograms in aluminum configurations. Furthermore, the profiles incorporate precise tolerances ensuring trolley wheels maintain proper alignment throughout operational life.

Multiple track profile sizes accommodate different load requirements and span configurations. For instance, lighter KBK track profiles suit applications handling components under 500 kilograms, while heavier-duty profiles support loads approaching system maximums. The standardized one-meter track increments enable precise system dimensioning matching facility layouts without requiring custom fabrication.

Modular Component Architecture

Beyond track systems, KBK cranes incorporate standardized components including suspension brackets, connectors, trolleys, hoists, and power distribution accessories. This modular architecture enables rapid system configuration combining off-the-shelf elements into customized solutions. Moreover, the building-block approach simplifies installation, reduces lead times, and enables cost-effective customization compared to engineered-to-order alternatives.

Suspension components attach track to building structures using adjustable brackets accommodating varying installation conditions. These mounting systems distribute loads properly while maintaining critical alignment tolerances. Additionally, connector elements join track sections, create curves, facilitate track switches, and enable complex three-dimensional routing matching material flow patterns.

Trolleys equipped with precision bearings ride within enclosed tracks, supporting hoists or direct load attachments. Consequently, patented articulating designs eliminate binding especially when handling loads at extreme bridge positions. The trolley articulation ensures smooth, effortless movement throughout the complete working envelope, improving operator efficiency and reducing physical strain.

Hoist and Load Handling Integration

KBK systems integrate with various hoist types including electric chain hoists, wire rope hoists, pneumatic balancers, and specialized load handling devices. Electric chain hoists represent the most common configuration, providing reliable lifting with capacities matching KBK structural ratings. These hoists feature variable speed controls enabling precise positioning essential for assembly operations and quality-sensitive material handling.

Pneumatic balancers and manipulators attached to KBK systems create zero-gravity handling environments where operators effortlessly position components regardless of weight. This ergonomic advantage reduces physical strain while improving positioning accuracy and assembly quality. Furthermore, specialized end effectors including vacuum lifters, magnetic grippers, and custom fixtures expand KBK capabilities beyond simple hook lifting.

Types and Configurations of KBK Crane Systems

KBK Monorail Systems

KBK monorail configurations employ single track installations guiding loads along linear or curved paths. These simple yet effective systems excel in sequential material delivery applications where components travel along defined production routes. For example, automotive assembly lines utilize KBK monorails delivering parts from storage areas to specific assembly stations following optimized flow patterns.

Monorail systems accommodate straight sections, curves with various radii, ascending and descending grades, and track switches enabling complex network configurations. Therefore, a single monorail installation can serve multiple workstations through strategic routing and switching arrangements. This flexibility makes monorails particularly valuable in facilities with space constraints or complex material flow requirements.

Installation options include ceiling-mounted configurations utilizing building structures and freestanding designs supported by independent columns. Ceiling-mounted monorails preserve valuable floor space while freestanding alternatives enable installation in facilities lacking adequate overhead support. Consequently, organizations select mounting approaches matching structural conditions and operational requirements.

KBK Single Girder Suspension Cranes

Single girder KBK suspension cranes combine two parallel runways supporting a traveling bridge equipped with trolley and hoist assembly. This configuration provides two-axis movement enabling load positioning throughout rectangular work areas. Specifically, the bridge travels along runway tracks while the trolley moves perpendicular along the bridge, creating complete X-Y coverage.

Typical spans range from 3 to 10 meters with runway lengths extending 20+ meters depending on facility layout. Load capacities reach 2,000 kilograms for aluminum systems and 3,200 kilograms for steel configurations. Moreover, the low-profile design minimizes headroom requirements critical in facilities with limited vertical clearance.

Single girder systems prove ideal for workstation applications including assembly cells, machining centers, packing stations, and quality inspection areas. The complete area coverage combined with smooth, precise positioning enables operators to efficiently handle components throughout the working envelope. Additionally, the lightweight construction permits installation on building structures with modest load capacity.

KBK Double Girder Suspension Cranes

Double girder KBK configurations utilize parallel composite beams increasing load-carrying capacity and enabling wider spans compared to single girder alternatives. The dual-rail construction provides enhanced rigidity maintaining precise alignment under heavier loads. Consequently, double girder systems handle components approaching maximum KBK capacity ratings across spans exceeding 10 meters.

The increased structural capacity makes double girder designs suitable for heavy assembly operations, material transfer in manufacturing cells, and applications requiring maximum lifting capability. However, the enhanced performance requires greater headroom compared to single girder equivalents. Organizations must balance capacity requirements against vertical space constraints when selecting between single and double girder configurations.

Pillar and Wall-Mounted Jib Cranes

KBK components create pillar-mounted jib cranes featuring rotating arms serving localized work areas. These configurations prove particularly effective for repetitive lifting tasks within defined radii. For instance, machine tool loading, welding stations, and packing operations benefit from jib crane accessibility without requiring complete area coverage systems.

Wall-mounted KBK jib cranes attach directly to building structures, eliminating floor-mounted columns that would otherwise obstruct work areas. This mounting approach maximizes usable floor space while providing lifting capability adjacent to walls or between structural columns. Furthermore, the compact footprint makes wall-mounted designs ideal for retrofitting lifting capacity into existing facilities with space limitations.

Freestanding Workstation Crane Systems

Freestanding KBK workstation cranes incorporate self-supporting column structures eliminating dependence on building support. These systems install directly on concrete floors anchored with foundation bolts, enabling lifting capability placement virtually anywhere within facilities. Moreover, the freestanding design permits installation without evaluating building structural capacity or requiring costly building modifications.

Three primary freestanding configurations serve different operational needs. Cantilever designs use columns on one side only, freeing opposite sides for equipment access and operator positioning. Standard portal configurations feature columns supporting both runway ends providing maximum stability for heavier loads. Additionally, lamppost designs offset column locations enabling equipment placement within existing machinery layouts with capacities reaching 2,000 kilograms.

Bridge lengths extend up to 46 feet with spans exceeding 34 feet available depending on capacity requirements. The engineered base structures require no cross bracing to buildings or field welding, simplifying installation and reducing project complexity. Consequently, freestanding systems provide flexible lifting solutions adapting to diverse facility layouts and operational requirements.

Key Advantages of KBK Crane Technology

Exceptional Modularity and Flexibility

The modular design philosophy represents KBK technology’s most compelling advantage. Organizations configure systems precisely matching specific requirements using standardized components. This approach avoids over-engineering while ensuring adequate capacity and coverage. Furthermore, modular systems adapt easily as production requirements evolve, extending equipment value throughout changing operational landscapes.

System modifications including track extensions, capacity upgrades, coverage area expansion, and workflow reconfiguration occur without replacing existing components. The building-block architecture enables cost-effective modifications implementing only necessary changes rather than complete system replacement. Consequently, KBK investments deliver sustained value across extended operational timelines accommodating production evolution.

Ergonomic Operation and Workforce Benefits

KBK systems dramatically improve workplace ergonomics by eliminating manual lifting of heavy components. The smooth, low-friction operation requires minimal operator effort for positioning loads throughout working envelopes. Moreover, precision control enables accurate component placement reducing physical strain and improving assembly quality.

Ergonomic improvements translate directly to reduced workplace injuries, decreased workers compensation costs, and improved employee satisfaction. Organizations implementing KBK technology consistently report fewer musculoskeletal complaints and enhanced operator productivity. Additionally, the reduced physical demands enable workforce diversity by eliminating strength requirements limiting participation in manual material handling roles.

Space Optimization Through Overhead Operation

Utilizing overhead space for material handling preserves valuable floor areas for production equipment, workstations, and material flow. This vertical space utilization proves particularly valuable in facilities with expensive real estate or constrained footprints. Specifically, overhead handling eliminates floor-based equipment including forklifts and pallet jacks that occupy space and create congestion.

The compact enclosed track profiles minimize headroom requirements compared to traditional overhead cranes. Low-headroom designs optimize vertical clearance in facilities with limited ceiling heights. Consequently, organizations maximize usable facility volume extracting value from three-dimensional space rather than solely horizontal floor areas.

Smooth, Precise Operation

Enclosed track designs with precision-engineered trolley systems deliver exceptionally smooth operation with minimal rolling resistance. The sealed bearings and protected running surfaces maintain consistent performance throughout equipment life. Therefore, operators position loads with precision and minimal effort improving assembly quality and cycle times.

Advanced articulating trolley designs eliminate binding when handling loads at extreme positions along bridge spans. This characteristic proves particularly valuable for long bridge configurations where traditional designs experience increased friction at end positions. Moreover, the smooth operation reduces mechanical wear extending component service life and minimizing maintenance requirements.

Clean Room and Specialized Environment Compatibility

KBK technology suits demanding environments including clean rooms, food processing facilities, and pharmaceutical manufacturing where contamination control proves critical. Specifically, aluminum systems with anodized surfaces meet stringent cleanliness standards while stainless steel configurations accommodate washdown requirements in food and pharmaceutical applications.

The enclosed track design prevents lubricant escape and particle generation that would otherwise contaminate sensitive processes. Furthermore, smooth surfaces facilitate cleaning and sanitization meeting regulatory requirements in controlled environments. This environmental adaptability expands KBK application scope beyond conventional manufacturing into specialized industries with elevated cleanliness standards.

Industrial Applications and Use Cases

Automotive Assembly and Manufacturing

Automotive manufacturers extensively deploy KBK systems throughout assembly lines handling components including body panels, engines, transmissions, seats, and interior assemblies. The precise positioning capability enables accurate component installation critical for quality and dimensional consistency. Moreover, the flexible routing accommodates just-in-time delivery strategies minimizing work-in-process inventory and space requirements.

Engine assembly operations utilize KBK systems positioning cylinder heads, intake manifolds, and accessory components during build sequences. The smooth operation prevents shock loads that could damage precision assemblies while enabling exact placement tolerances. Consequently, automotive facilities achieve quality targets while maintaining production efficiency.

Electronics and Precision Component Manufacturing

Electronics manufacturing relies on KBK technology for handling circuit boards, displays, battery assemblies, and finished products throughout production sequences. The vibration-dampening characteristics prevent damage to sensitive components during transport and positioning. Additionally, clean room compatible configurations meet contamination control requirements essential for semiconductor and display manufacturing.

Precision assembly operations benefit from exact positioning capability enabling accurate component mating and fastening. For instance, display bonding processes require precise alignment maintained throughout adhesive curing cycles. KBK systems provide stable, controlled positioning meeting these demanding requirements while maintaining production throughput.

Aerospace Component Handling

Aerospace manufacturing handles large, high-value components requiring damage-free transport and precise positioning. KBK systems equipped with specialized end effectors safely manipulate wing sections, fuselage panels, and propulsion components throughout fabrication and assembly processes. Furthermore, the smooth operation prevents shock loading that could compromise structural integrity or surface finishes.

Composite component manufacturing particularly benefits from KBK technology as the lightweight yet strong profiles accommodate large envelope requirements without excessive dead weight. The precise control enables accurate layup operations and autoclave loading critical for composite quality and dimensional consistency.

Food and Beverage Processing

Food processing facilities implement stainless steel KBK systems meeting sanitation requirements while providing efficient ingredient handling and finished product transport. Washdown-rated configurations withstand regular cleaning protocols required in food manufacturing environments. Moreover, the overhead handling prevents floor contamination and facilitates thorough cleaning of production areas.

Packaging operations utilize KBK systems transferring filled containers from production lines to palletizing stations or storage areas. The smooth operation prevents product damage while maintaining throughput necessary for high-volume food production. Additionally, the enclosed track design prevents lubricant contamination critical in direct-food-contact applications.

Clean Room and Pharmaceutical Manufacturing

Pharmaceutical manufacturing demands the highest cleanliness standards requiring specialized material handling solutions. KBK aluminum systems with anodized surfaces generate minimal particulates while facilitating thorough cleaning and sanitization. Furthermore, the enclosed design prevents lubricant escape maintaining clean room integrity essential for pharmaceutical quality.

Active pharmaceutical ingredient handling requires precise positioning combined with contamination control throughout production sequences. KBK systems deliver both capabilities enabling manufacturers to meet stringent regulatory requirements while maintaining operational efficiency. Consequently, pharmaceutical facilities rely on KBK technology for critical material handling operations affecting product quality and regulatory compliance.

Installation and Implementation Considerations

Structural Requirements and Building Integration

KBK systems require adequate building structure support for ceiling-mounted installations. Professional structural engineers following AISC guidelines evaluate existing building capacity determining whether reinforcement proves necessary before installation.Specifically, runway support points must accommodate crane loads plus dynamic factors resulting from material handling operations.

New construction projects integrate KBK support requirements into building design eliminating costly retrofits. Structural designers specify adequate column capacity, roof beam strength, and foundation support accommodating planned crane systems. This proactive approach optimizes building structures for material handling requirements while controlling construction costs.

Freestanding systems eliminate building structure dependencies by supporting loads through independent columns anchored directly to concrete floors. The self-supporting design requires adequate floor thickness and reinforcement handling anchor bolt forces. Consequently, concrete floor assessments determine whether existing slabs provide sufficient capacity or require reinforcement before freestanding crane installation.

System Design and Capacity Planning

Proper system design begins with detailed load analysis identifying maximum component weights, rigging equipment requirements, and operational duty cycles. Organizations must account for occasional peak loads exceeding normal operations while avoiding excessive overdesign increasing costs unnecessarily. Therefore, accurate load assessment balances safety factors against economic considerations.

Coverage area requirements determine runway lengths, bridge spans, and overall system configuration. Material flow analysis identifies optimal crane positioning minimizing travel distances and cycle times. Furthermore, the evaluation considers future production changes enabling systems to accommodate anticipated growth without requiring complete redesign.

Duty cycle classification determines component specifications and expected service life. Continuous production applications require heavy-duty components while intermittent operations accommodate standard-duty selections. Consequently, accurate duty assessment ensures appropriate component specification balancing initial investment against long-term reliability.

Safety Features and Regulatory Compliance

KBK systems incorporate multiple safety features protecting operators and preventing equipment damage. Overload prevention devices refuse lift commands exceeding rated capacity eliminating dangerous overload conditions. Moreover, end stops prevent trolley and bridge travel beyond safe limits while limit switches protect against over-travel conditions.

Emergency stop controls enable immediate equipment shutdown during unsafe conditions. Pendant controls and radio remote systems feature deadman switches requiring continuous operator activation preventing unintended movement. Additionally, warning devices including lights and audible alarms alert personnel to crane operation improving workplace safety.

Monorail Manufacturers Association certification demonstrates compliance with industry safety standards. MMA-certified systems meet rigorous requirements for design, manufacturing, and testing ensuring reliable, safe operation. Organizations specifying MMA-certified equipment demonstrate commitment to workplace safety while potentially reducing liability exposure and insurance costs.

Cost Considerations and Return on Investment

Initial Investment Factors

KBK crane costs vary significantly based on configuration complexity, load capacity, coverage area, and feature specifications. Basic monorail installations handling 500 kilograms over short distances may cost $5,000-$15,000 for complete systems including track, trolley, and hoist. In contrast, comprehensive freestanding workstation cranes with 2,000 kilogram capacity and 10-meter spans require investments of $30,000-$80,000 depending on specifications.

Aluminum systems typically command 15-25% premiums over equivalent steel configurations due to material costs and specialized manufacturing. However, the corrosion resistance and reduced weight justify premiums in applications requiring these characteristics. Furthermore, clean room and food-grade specifications add 20-35% to base costs reflecting specialized materials and manufacturing processes.

Installation costs depend on system complexity and site conditions. Simple ceiling-mounted monorails may require only $1,000-$3,000 for professional installation. Conversely, extensive freestanding systems with multiple bridges and complex routing necessitate $10,000-$25,000 installation investments including foundation work, alignment verification, and system commissioning.

Operational Cost Advantages

Energy consumption for KBK systems remains minimal due to efficient enclosed track designs and modern hoist technology. Electric chain hoists consume 1-3 kilowatts during operation translating to modest annual energy costs for typical duty cycles. Moreover, the smooth operation reduces peak demand compared to less-efficient alternatives.

Maintenance requirements prove minimal due to enclosed track protection and quality components. Annual inspection and lubrication typically cost $500-$2,000 depending on system size and complexity. Furthermore, component longevity extends 15-20 years under normal operating conditions minimizing replacement expenses throughout ownership periods.

The ergonomic benefits reduce workers compensation costs and improve productivity. Organizations implementing KBK technology report 20-30% productivity improvements in material handling operations combined with measurable workplace injury reductions. These operational benefits generate substantial returns justifying initial investments.

Calculating Return on Investment

ROI analysis should account for multiple benefit categories including labor efficiency gains, quality improvements, space utilization optimization, and safety enhancements. Labor savings result from faster cycle times and reduced handling requirements. Quality improvements stem from precise positioning and damage-free handling reducing rework and scrap.

Space optimization enables facility expansion without building additions or facility relocation. Utilizing overhead volume rather than floor space accommodates production growth within existing footprints. Additionally, workplace safety improvements reduce insurance premiums, workers compensation costs, and regulatory compliance expenses.

Typical payback periods range from 18-36 months for manufacturing applications with measurable productivity improvements. Consequently, the investments deliver positive returns throughout extended service lives providing sustained operational value and competitive advantages.

Future Trends in KBK Crane Technology

Automation and Smart Manufacturing Integration

Modern KBK systems increasingly incorporate automation features including programmable movement sequences, integration with manufacturing execution systems, and coordination with robotic assembly equipment. These intelligent capabilities enable automated material delivery matching production schedules without manual intervention. Moreover, the integration supports Industry 4.0 initiatives transforming traditional manufacturing into connected smart factories.

Sensor technology enables real-time load monitoring, position feedback, and operational status reporting. IoT connectivity transmits performance data to cloud-based analytics platforms identifying optimization opportunities and predicting maintenance requirements. Consequently, organizations leverage operational intelligence improving efficiency and reducing unplanned downtime.

Energy Efficiency and Sustainability

Environmental considerations drive development of energy-efficient KBK technologies including regenerative braking systems recovering energy during lowering operations. LED lighting upgrades reduce power consumption while improving visibility. Furthermore, sustainable manufacturing processes minimize environmental impact throughout equipment lifecycles.

Lightweight aluminum systems reduce material consumption and energy requirements during manufacturing. The extended service life combined with recyclability at end-of-life supports circular economy principles. Organizations increasingly value sustainable equipment selections supporting corporate environmental commitments and regulatory compliance.

Advanced Materials and Component Innovation

Ongoing material science advances enable stronger, lighter track profiles expanding capability while reducing weight. Composite materials offer corrosion resistance combined with structural efficiency. Additionally, advanced coatings improve durability in challenging environments extending service life and reducing maintenance.

Component miniaturization reduces system envelope enabling lower-profile installations optimizing vertical space utilization. Compact hoist designs with high power density maintain lifting performance while reducing headroom requirements. These innovations expand KBK application scope into facilities with extreme space constraints.

Conclusion: KBK Cranes as Essential Manufacturing Infrastructure

KBK cranes represent sophisticated modular lifting solutions combining flexibility, precision, and ergonomic operation essential for modern manufacturing environments. The standardized component architecture enables customized configurations matching specific operational requirements while maintaining cost-effectiveness and implementation efficiency. Load capacities spanning 125 kilograms to 3,200 kilograms accommodate diverse applications from electronics assembly to aerospace component handling.

The exceptional modularity ensures KBK investments deliver sustained value throughout evolving production landscapes. Organizations modify, expand, and reconfigure systems matching changing requirements without replacing foundational infrastructure. This adaptability, combined with smooth operation, space-efficient design, and ergonomic benefits, explains KBK technology’s dominant position in workstation material handling applications.

Over 50 years of continuous development and refinement establish KBK systems as proven, reliable technology serving demanding industrial applications worldwide. The combination of German engineering heritage, modular flexibility, and ongoing innovation ensures KBK cranes remain essential infrastructure supporting efficient, safe, and profitable manufacturing operations into the foreseeable future.

Organizations evaluating workstation crane requirements should carefully assess KBK technology’s unique advantages addressing material handling challenges while providing long-term operational value and competitive positioning in increasingly demanding industrial markets.

Pricing Disclaimer and Important Notice

The information presented in this guide regarding KBK cranes is provided for general educational purposes only. All technical specifications, configurations, and capabilities described represent typical system characteristics based on industry standards and manufacturer documentation. Actual system performance may vary based on specific configurations, operating conditions, environmental factors, and proper maintenance practices.

This guide does not constitute technical specifications, performance guarantees, or purchasing recommendations. Organizations considering KBK crane systems should:

- Consult with qualified system integrators to determine appropriate configurations for specific applications

- Conduct thorough load analysis with professional engineers ensuring proper capacity selection

- Verify building structural adequacy before finalizing system designs and configurations

- Obtain detailed proposals from multiple qualified suppliers including complete specifications and pricing

- Review safety requirements and ensure compliance with applicable regulations and standards

No warranty is provided regarding the accuracy, completeness, or suitability of information for any particular application. System selection, design, installation, and operation should occur under guidance of qualified professionals familiar with specific operational requirements and applicable regulations.

For accurate, application-specific information, please contact certified KBK system providers, manufacturers, or qualified material handling consultants who can evaluate unique requirements and provide appropriate technical recommendations and specifications.

This disclaimer applies to all technical information, specifications, capabilities, and application examples presented throughout this guide.

Need Expert Guidance? If you have technical questions or require professional product quotations, please contact us for free technical consultation anytime.