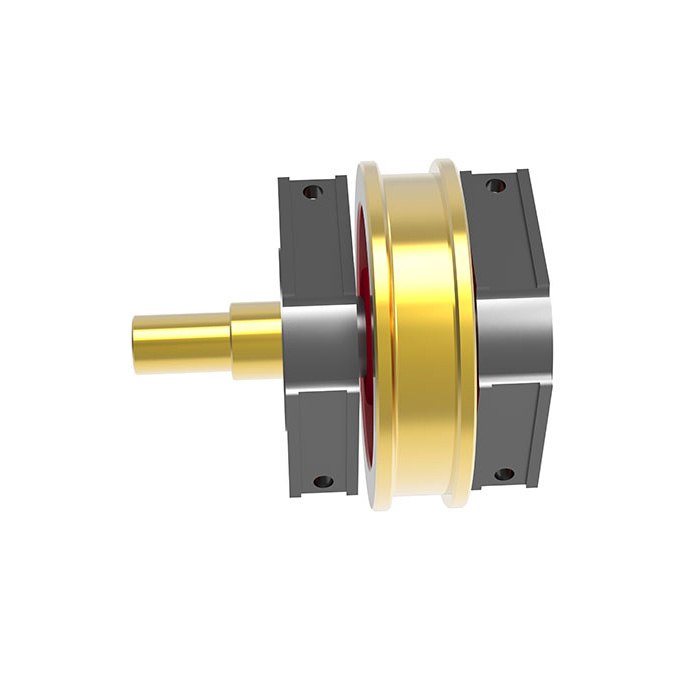

Crane Wheel Set 3-1000 – Robust and Reliable Travel Solution

Introduction

The Crane Wheel Set is a critical component designed for smooth crane movement and precise load positioning in demanding industrial applications. Combining high-strength forged or cast steel wheels, precision bearings, and reinforced axles, these wheel assemblies deliver exceptional durability and performance. Ideal for manufacturing, steel production, construction, and logistics, they ensure reliable operation across diverse industries.

Technical Specifications and Performance Features

The Crane Wheel Set is engineered for robust performance, supporting a load capacity of 1-500 tons per wheel set and featuring wheel diameters from 125 to 800 mm. Built to meet ISO, CE, and GB3811 standards, these wheel sets ensure reliability in challenging environments. Key specifications include:

- Model: LD, QD, European standard wheel sets (3~1000)

- Load Capacity: 1-500 tons per wheel set

- Wheel Diameter: 125 ~ 800 mm

- Wheel Material: Cast iron, cast steel, 40Cr, 42CrMo, 65Mn

- Bearing Type: Spherical bearings, tapered rollers

- Operating Temperature: -40°C to +200°C

- Hardness: HB300-400 (wheel tread)

- Product Certification: ISO, CE

- Design Standard: GB3811

These specifications ensure smooth travel and precise load handling in a wide range of industrial applications.

Mechanical Design Features

The Crane Wheel Set is constructed with premium components for durability and efficiency:

- High-strength wheels: Forged or cast steel (42CrMo, 65Mn) for superior strength and wear resistance

- Precision bearings: Double-row spherical rollers or tapered rollers handle radial and axial loads

- Reinforced axles: Forged high-strength steel ensures fatigue resistance and reliability

- Advanced sealing: Protects bearings from contamination for extended service life

- CNC-machined treads: Ensures accurate rail contact and smooth operation

- Protective coatings: Enhances corrosion resistance for harsh environments

- Optional temperature sensors: Monitors operating conditions for added safety

These features combine to deliver a robust and reliable travel solution for heavy-duty cranes.

Operational Features

The Crane Wheel Set is designed for optimal performance and versatility:

- Smooth travel: Precision bearings ensure quiet and vibration-free operation

- High load distribution: Optimizes contact stress for stable performance

- Alignment accuracy: Maintains precise wheel geometry for reliable movement

- High-speed capability: Supports travel speeds up to 200 m/min

- Vibration damping: Reduces noise and structural stress for enhanced durability

These features ensure efficient and precise crane movement across various applications.

Safety and Protection Systems

Safety and reliability are prioritized with the following features:

- Advanced sealing systems: Prevents ingress of dust and contaminants

- Corrosion-resistant coatings: Protects components in harsh environments

- Temperature monitoring (optional): Ensures safe operation under extreme conditions

- Stress-optimized axles: Engineered to resist fatigue and ensure stability

- Robust bearing systems: Handles high radial and axial loads securely

These protective measures enhance operational safety and component longevity.

Installation and System Integration

The Crane Wheel Set is designed for seamless integration and ease of installation:

- Flexible configurations: Supports LD, QD, and European standard crane systems

- Easy installation: Complete assemblies reduce setup time

- Crane compatibility: Integrates with overhead, gantry, and tower crane systems

- Precision alignment: Ensures accurate wheel positioning during installation

This adaptability makes the wheel set suitable for a wide range of crane setups.

Control System Compatibility

The wheel set supports efficient crane operation through:

- Standard crane integration: Compatible with existing crane control systems

- Precision alignment features: Enhances control accuracy for smooth travel

- Optional monitoring systems: Supports integration with temperature and load sensors

- Robust axle design: Ensures stability during dynamic crane operations

These features ensure reliable performance in complex crane systems.

Technical Performance Data

The Crane Wheel Set delivers consistent performance with the following specifications:

- Model: LD, QD, European standard wheel sets (3~1000)

- Load Capacity: 1-500 tons per wheel set

- Wheel Diameter: 125 ~ 800 mm

- Wheel Material: Cast iron, cast steel, 40Cr, 42CrMo, 65Mn

- Bearing Type: Spherical bearings, tapered rollers

- Operating Temperature: -40°C to +200°C

- Hardness: HB300-400 (wheel tread)

- Certifications: ISO, CE

- Design Standard: GB3811

These specifications ensure dependable performance in demanding industrial environments.

Quality Manufacturing Standards

The Crane Wheel Set adheres to stringent manufacturing protocols:

- Material traceability: Full steel certification documentation provided

- CNC precision manufacturing: Ensures dimensional accuracy and consistency

- Dynamic balance testing: Guarantees smooth and vibration-free operation

- Comprehensive quality inspection: 100% dimensional and hardness verification

- Certified standards: Meets ISO 4301, FEM 1.001, CMAA, and GB3811 requirements

- Standard warranty: Offers user confidence and support

These standards ensure a high-quality, reliable product for industrial applications.

Application Suitability

The Crane Wheel Set is ideal for a variety of industries requiring robust travel solutions:

- Manufacturing and production: Supports assembly line overhead cranes and material handling systems

- Steel and metallurgy: Powers ladle cranes and coil handling equipment in high-temperature environments

- Construction and infrastructure: Used in tower and gantry crane systems for bridge construction

- Logistics and warehousing: Facilitates storage, retrieval, and bulk material handling

- Shipbuilding and aerospace: Enables heavy-duty cranes for oversized component handling

Its versatility makes it suitable for demanding lifting applications across multiple sectors.

Technical Support and Configuration

For optimal performance, the wheel set includes comprehensive support:

- Professional installation guidance: Ensures correct setup and alignment

- Technical consultation: Available for system integration and customization

- Detailed documentation: Includes user manuals and technical specifications

- Ongoing support: Ensures long-term reliability and performance

Contact our team for tailored configuration and integration assistance.

Maintenance Requirements

To maintain peak performance, the Crane Wheel Set requires:

- Regular inspections: Check wheel treads, bearings, and axles for wear

- Lubrication schedules: Use premium synthetic greases for bearings

- Alignment checks: Ensure proper wheel geometry and rail contact

- Corrosion monitoring: Inspect coatings in harsh environments

- Periodic maintenance: Follow manufacturer guidelines for longevity

Adhering to these practices minimizes downtime and extends service life.

Call to Action

Enhance your crane operations with the Crane Wheel Set 3-1000. Contact our team today for expert guidance on configuration, installation, and integration to meet your industrial lifting needs. Ensure smooth, reliable, and safe crane movement with this high-performance solution.

Reviews

There are no reviews yet.