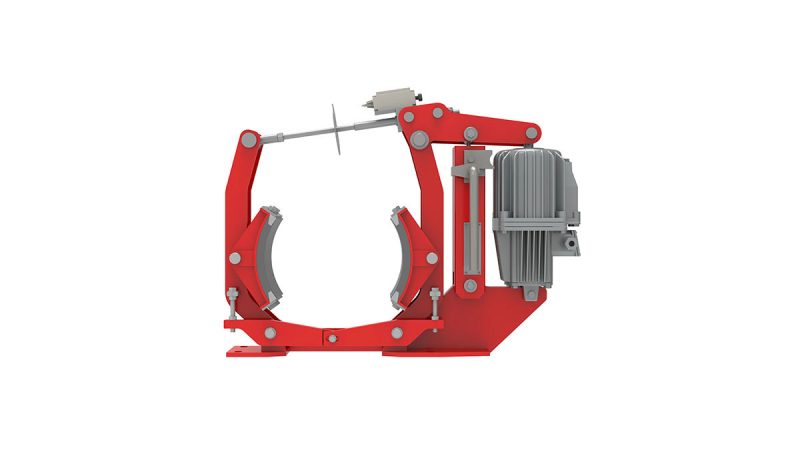

Hydraulic Brake for Gantry Cranes 5-500 kN – Precision Safety Solution

Introduction

The Hydraulic Brake for Gantry Cranes is a critical safety component for double-beam gantry cranes. Engineered for heavy-duty applications, it provides exceptional braking force, smooth deceleration, and reliable performance in extreme conditions.

Technical Specifications and Performance Features

Delivers 5-500 kN braking force with <0.2s response time. Key specs:

- Braking Force: 5-500 kN (customizable)

- Operating Pressure: 16-25 MPa

- Response Time: <0.2 seconds

- Operating Temperature: -30°C to +80°C

- Brake Disc Material: Hardened steel/cast iron

- Service Life: 2+ million cycles

- Safety Standard: CE, ISO 9001, OSHA compliant

Ensures precise stopping for loads up to 500 tons.

Mechanical Design Features

- Premium hydraulic components: Pumps, valves, cylinders

- Corrosion-resistant materials: Stainless steel, protective coatings

- Advanced sealing: Leak-proof, contamination-resistant

- Modular design: Easy replacement/servicing

- Self-adjusting tech: Automatic wear compensation

Operational Features

- Instant response: <0.2s emergency stops

- Variable force: Proportional to load weight

- Smooth deceleration: Prevents swing/damage

- Position accuracy: ±5mm

- Programmable modes: Adaptable settings

Safety and Protection Systems

- Anti-Lock System (ABS): Prevents wheel lock-up

- Fail-Safe Design: Auto-engages on pressure drop

- Redundant circuits: Backup braking

- Load monitoring: Adjusts force dynamically

- Weather resistant: -30°C to +80°C reliability

Installation and System Integration

- Modular setup: Quick integration

- Universal compatibility: Double-beam gantry cranes

- Low maintenance: Fewer parts

- Professional installation: Available support

Control System Compatibility

- Precision control: Proportional braking

- Crane interface: Standard integration

- Programmable settings: Operational modes

- Load-based adjustment: Safety circuits

Technical Performance Data

- Braking Force: 5-500 kN

- Pressure: 16-25 MPa

- Response: <0.2s

- Temperature: -30°C to +80°C

- Disc Material: Hardened steel/cast iron

- Cycles: 2M+

- Standards: CE, ISO 9001, OSHA

Quality Manufacturing Standards

- Robust construction: Premium components

- Corrosion protection: Coatings/seals

- Testing: 125% overload, endurance

- Certifications: CE, ISO 9001, OSHA

- Warranty: Standard coverage

Application Suitability

- Heavy Construction: Bridge/high-rise cranes

- Steel & Manufacturing: Mill/assembly ops

- Ports & Logistics: Container/shipyard handling

- Mining & Energy: Ore/power plant equipment

Technical Support and Configuration

- Installation services: Professional guidance

- Customization: Force/pressure options

- Documentation: Specs/guides

- Support: Ongoing optimization

Maintenance Requirements

- Inspections: Fluid, seals, discs

- Self-adjusting: Minimal intervention

- Fluid checks: Pressure/seals

- Cycle monitoring: Wear verification

- Protocols: Reduce downtime

Call to Action

Secure your gantry crane with Hydraulic Brake for Gantry Cranes. Contact us for custom solutions and installation.

Reviews

There are no reviews yet.