KBK Cranes | Modular Workstation Systems

Showing all 4 results

FAQ

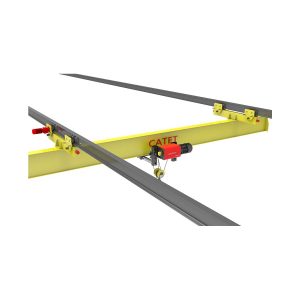

KBK stands for "Kombinierte Kranbalken" (Combined Crane Beam). It's a modular, lightweight aluminum track system that offers flexible material handling solutions with quick installation, easy reconfiguration, and minimal building load requirements compared to traditional crane systems.

Our KBK systems handle loads from 125kg up to 2000kg (2 tons). For heavier applications, we can design double-beam configurations or recommend our light-duty bridge crane systems.

Absolutely! This is a key advantage of KBK systems. The modular design allows easy expansion, reconfiguration, or relocation as your production needs change. Additional track sections, curves, switches, and workstations can be added without major disruption.

Suspension KBK cranes hang from ceiling structures, saving floor space and allowing movement underneath. Floor-supported systems use columns when ceiling support is inadequate or unavailable. Both offer the same load capacity and flexibility.

KBK systems typically install 50-70% faster than traditional cranes due to the lightweight modular components. A basic system can be operational in 1-3 days. Complex configurations with multiple tracks and workstations may take 1-2 weeks.