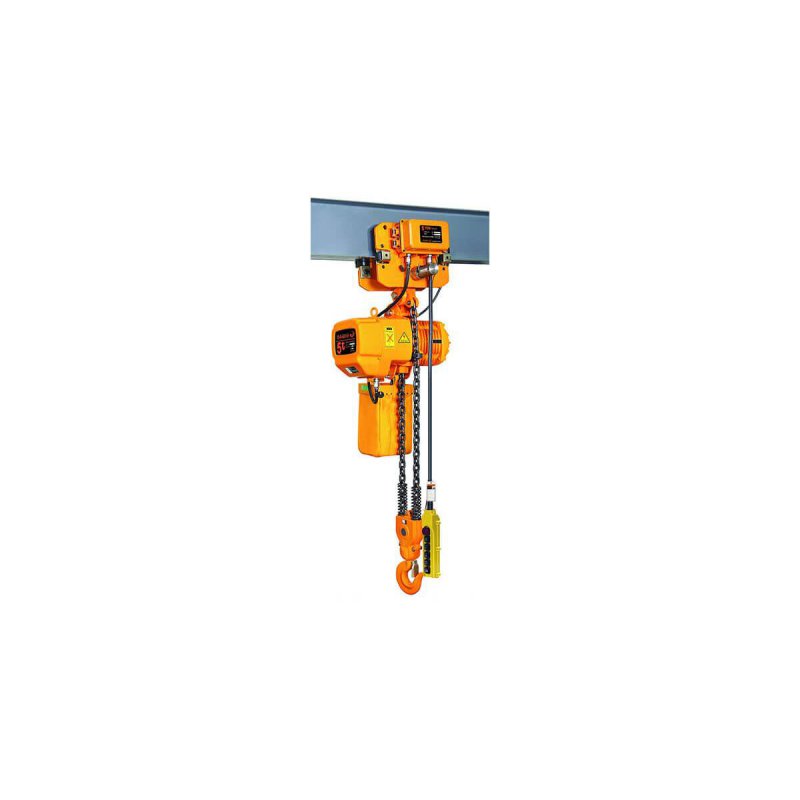

Industrial Chain Hoist 0.5-50T – Robust Lifting Solution

The Industrial Chain Hoist 0.5-50T is a precision-engineered lifting solution designed for safe, efficient, and versatile material handling across a wide range of industrial applications. Powered by a high-performance electric motor and equipped with a durable chain system, this hoist delivers reliable operation in manufacturing facilities, warehouses, and construction sites. Its compact design optimizes workspace while providing exceptional lifting capacity from 0.5 to 50 tons, meeting diverse operational needs with advanced engineering and compliance with GB3811 design standards.

What is an Electric Hoist Winch | Complete Guide 2025

Technical Specifications and Performance Features

The Industrial Chain Hoist offers a rated load capacity of 0.5 to 50 tons, with a work level classification of M3 to M4, ensuring suitability for varying operational intensities. It supports a lifting height range of 4 to 30 meters and operates on a flexible power supply of 200 to 600 volts. Certified to ISO and CE standards, this hoist guarantees compliance with global quality and safety requirements, delivering consistent performance across diverse industrial environments.

Mechanical Design Features

The hoist is constructed with high-quality components for durability and operational efficiency:

- High-Performance Electric Motor: Delivers reliable power for consistent lifting.

- Heavy-Duty Lifting Chain: Handles loads from 0.5 to 50 tons with precision.

- Low-Maintenance Gearbox: Ensures stable operation with minimal upkeep.

- Precision Bearings: Facilitates smooth and efficient load movement.

- Aluminum Housing: Enhances heat dissipation for extended motor life.

- Electromagnetic Brake System: Provides immediate load-holding capability.

- IP55 Protection Rating: Ensures reliability in harsh industrial conditions.

These components are engineered to withstand demanding environments, ensuring long-term performance and reliability.

Operational Features

The Industrial Chain Hoist provides:

- High Lifting Speeds: Enhances productivity for rapid load handling.

- Precise Load Control: Ensures accurate positioning for delicate operations.

- Energy Efficiency: Reduces operational costs through optimized power usage.

- Consistent Performance: Maintains reliability across the full capacity range.

This configuration supports efficient material handling, catering to both high-speed and precision-focused tasks.

Safety and Protection Systems

The hoist incorporates advanced safety features for secure operations:

- Electromagnetic Brake: Ensures immediate and reliable load holding.

- IP55 Environmental Protection: Guards against dust and water ingress.

- Overload Protection System: Prevents damage from excessive loads.

- Emergency Stop Functionality: Enables rapid response in critical situations.

- Thermal Motor Protection: Safeguards against overheating during intensive use.

Installation and System Integration

The chain hoist is designed for versatile installation and seamless system integration:

- Flexible Mounting Options: Adapts to various industrial configurations.

- Crane Beam Compatibility: Integrates with standard crane structures.

- Standardized Control Interfaces: Simplifies connection to existing systems.

Control System Compatibility

The hoist supports:

- Pendant Control Systems: Provides user-friendly operation.

- Optional Remote Control: Enhances operational flexibility.

- Crane Control Integration: Compatible with existing crane setups.

- Safety Circuit Connections: Supports emergency stop integration.

Technical Performance Data

Standard Specifications:

- Model: Industrial Chain Hoist 0.5-50T

- Rated Load: 0.5 to 50 tons

- Work Level: M3 to M4

- Lifting Height: 4 to 30 meters

- Power Supply: 200 to 600 V

- Product Certification: ISO, CE

- Design Standard: GB3811

- Brake System: Electromagnetic

Performance Features:

- Operation: High-efficiency electric motor control

- Lifting Capability: Smooth handling across full capacity range

- Environmental Protection: IP55 rating for dust and water resistance

Quality Manufacturing Standards

The Industrial Chain Hoist adheres to CATET’s stringent manufacturing protocols:

- Precision Assembly: Ensures consistent quality and performance.

- Comprehensive Testing: Includes chain and motor inspections.

- Quality Control Protocols: Guarantees compliance with ISO and CE standards.

- Standard Warranty: Provides coverage for operational confidence.

- Detailed Documentation: Supports installation, operation, and maintenance.

Application Suitability

This chain hoist is ideal for a variety of industrial environments:

- Manufacturing Facilities: Supports efficient and flexible lifting operations.

- Warehousing Operations: Enables rapid and precise load handling.

- Construction Sites: Delivers reliable performance for heavy-duty tasks.

- Maintenance Workshops: Offers versatile control for diverse lifting needs.

Technical Support and Configuration

For optimal performance and integration:

- Professional Installation: Recommended for complex setups.

- Technical Consultation: Available for system customization and integration.

- Comprehensive Documentation: Guides installation and operation.

- Ongoing Support: Ensures long-term operational reliability.

Maintenance Requirements

To maintain peak performance, the hoist requires:

- Regular Inspections: Per CATET’s maintenance schedules.

- Chain Maintenance: Periodic inspection and replacement as needed.

- Brake System Checks: Ensures reliable load-holding performance.

- Electrical System Monitoring: Verifies connection integrity.

- Lubrication Schedules: Maintains smooth mechanical operation.

For tailored configurations, installation guidance, or technical support, contact CATET’s dedicated support team to optimize your industrial lifting operations.

Ready to enhance your material handling efficiency? Contact Us for Detailed Specifications

Reviews

There are no reviews yet.