Double Girder Overhead Crane Installation for Industrial Facilities | 2025 Complete Guide

Double girder overhead crane installation represents one of the most critical investments in material handling infrastructure for modern industrial facilities. This comprehensive guide provides detailed insights into the installation process, drawing from real-world projects and industry-standard practices to help facility managers, engineers, and project planners navigate this complex undertaking successfully.

Understanding Installation Scope and Timeline

Successful double girder overhead crane installation typically requires 3 to 6 weeks for completion, depending on facility size and crane specifications. For instance, a manufacturing plant in Ohio recently completed a 50-ton capacity system installation in 28 days, including all preparatory work and commissioning. However, larger systems exceeding 100-ton capacity may extend to 8-10 weeks, particularly when extensive structural modifications are necessary.

Project timelines break down into distinct phases. Pre-installation preparation generally consumes 30-40% of the total schedule, followed by physical installation at 40-50%, and testing plus commissioning accounting for the remaining 10-20%. Consequently, proper planning during early stages significantly impacts overall project success and reduces unexpected delays.

Furthermore, weather conditions can affect outdoor preparation work, while production schedules in active facilities may limit installation windows to night shifts or weekends. Therefore, realistic timeline estimation must account for these operational constraints alongside technical requirements.

Pre-Installation Assessment and Building Evaluation

Before beginning any double girder overhead crane installation, structural engineers must thoroughly evaluate the building’s load-bearing capacity. According to AISC standards, runway beam support structures must withstand the combined crane weight, maximum rated load, and dynamic forces generated during operation. Specifically, calculations should include a minimum safety factor of 1.5 for static loads and account for impact forces typically ranging from 25% to 50% of the lifted load.

A comprehensive structural assessment examines column spacing, foundation integrity, roof structure adequacy, and existing utilities. Moreover, buildings constructed before 1990 often require reinforcement, as modern crane systems generate significantly higher concentrated loads than older designs anticipated. Real-world data shows that approximately 35% of installations in retrofitted facilities need some degree of structural enhancement.

Additionally, concrete foundations supporting runway columns must meet minimum compressive strength requirements of 3,000 to 4,000 PSI. Settlement tolerances become critical here, as differential settlement exceeding 1/4 inch per 20 feet can cause operational issues and premature wear on crane components.

Equipment and Resource Requirements

Successful dual-beam bridge crane setup demands substantial equipment mobilization. Mobile cranes form the backbone of installation operations, with capacity requirements typically ranging from 60 to 200 tons depending on the installed crane’s specifications. For example, installing a 30-ton capacity system with a 60-foot span usually requires a 100-ton mobile crane for main girder placement.

In addition to primary lifting equipment, installations require scissor lifts or boom lifts for elevated work, welding equipment meeting AWS D1.1 standards, precision measuring instruments including laser alignment systems, and electrical testing equipment. Labor requirements typically include a project manager, structural engineers, certified riggers, licensed electricians, welders with appropriate certifications, and millwrights experienced in crane installation.

Labor costs constitute 40-55% of total installation expenses, with typical teams comprising 6-10 skilled tradespeople working 10-12 hour shifts during peak installation phases. Therefore, workforce planning and scheduling coordination become essential for cost control and timeline adherence.

Runway System Installation and Alignment Specifications

The runway rail installation establishes the foundation for reliable crane operation. Rail alignment tolerances according to CMAA Specification #70 allow maximum deviation of 1/4 inch over any 10-foot span, with overall straightness within 1/2 inch over the entire runway length. These stringent requirements necessitate specialized surveying equipment and experienced installation crews.

Installation begins with runway beam placement and leveling. Support beams must achieve level within 1/8 inch per 10 feet longitudinally and 1/16 inch per foot transversely. Subsequently, rail mounting proceeds using specially designed clamps or welded connections, depending on design specifications. Welding procedures must comply with AWS D1.1 standards, requiring certified welders and documented weld procedures.

Rail joints receive particular attention during installation. Expansion joints accommodate thermal expansion, typically spaced every 150-200 feet in climate-controlled environments or more frequently in facilities with significant temperature variations. Moreover, joint gaps must maintain precision alignment to prevent wheel damage and ensure smooth crane travel. Industrial facilities in regions with extreme temperature swings may experience rail length changes of 1/4 inch per 100 feet per 50°F temperature variation.

Main Girder Assembly and Installation Process

Installing the primary bridge girders represents the most critical and potentially hazardous phase of double girder overhead crane installation. These massive structural components typically weigh between 15,000 to 80,000 pounds for standard industrial applications, requiring meticulous planning and execution. A recent automotive manufacturing facility installation involved positioning two 42-foot main beams, each weighing 28,000 pounds, using a 150-ton mobile crane positioned outside the building.

Rigging calculations must account for lifting point locations, sling angles, and dynamic loading during the lift. Professional riggers typically use multiple-part slings with safety factors of 5:1 minimum, following ASME B30.9 standards. Furthermore, wind speeds exceeding 15 mph generally necessitate postponing outdoor lifting operations due to safety concerns.

Once hoisted to elevation, girders undergo precise positioning within mounting brackets or on end trucks. Alignment tolerances require the span measurement within 1/8 inch of specifications and diagonal measurements equal within 1/4 inch to ensure square installation. Shimming and adjustment procedures typically consume 4-6 hours per girder, as installers methodically verify all dimensional requirements before final securing.

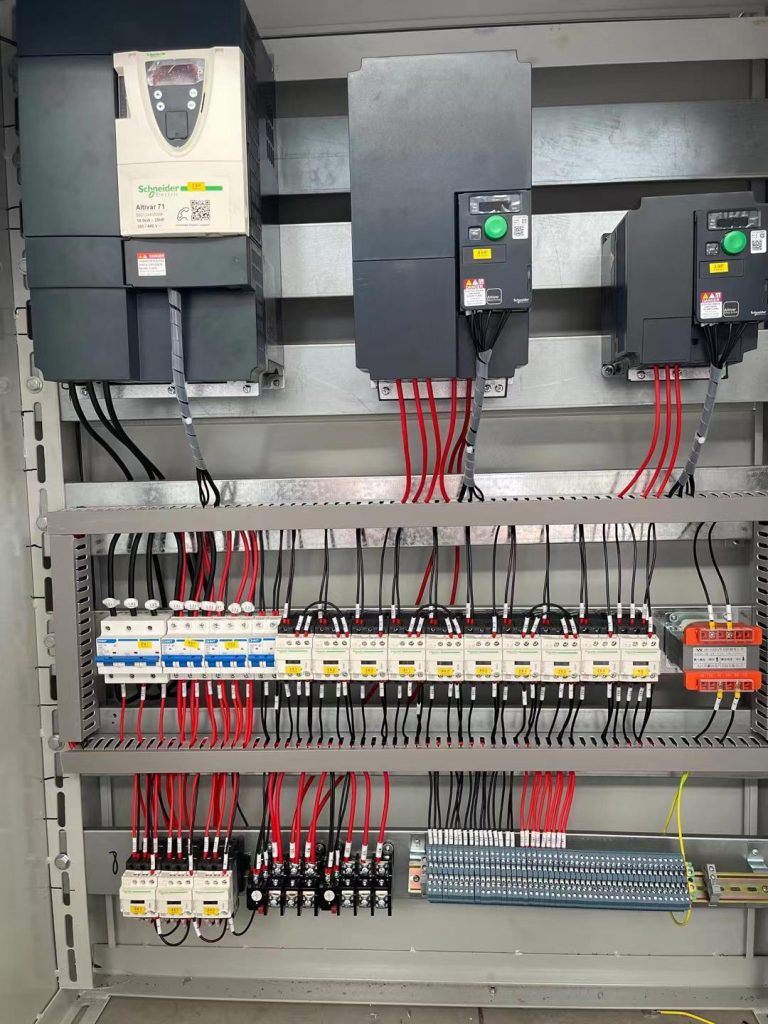

Electrical System Integration and Controls

Electrical installation for dual-beam overhead lifting systems encompasses power distribution, control systems, and safety interlocks. Power requirements vary substantially based on crane capacity and duty cycle, with typical installations requiring 480V three-phase service delivering 60-200 amperes. A manufacturing facility in Michigan recently installed a 40-ton system requiring a dedicated 480V, 150A circuit with appropriate overcurrent protection and disconnect switches.

Cable festoon systems or conductor bars provide mobile power delivery to the crane bridge and trolley. Installation must maintain proper clearances from structural elements, with NFPA 70 requiring minimum spacing of 2.5 inches for voltages up to 600V. Additionally, cable management systems need sufficient slack to accommodate full crane travel without creating mechanical stress on connections.

Control panel installation typically occurs at floor level or on elevated platforms, providing operators clear visibility of the work area. Modern systems incorporate variable frequency drives (VFDs) for smooth acceleration and deceleration, reducing mechanical stress and extending component life. Safety features mandated by OSHA include emergency stop circuits, overload protection systems, limit switches preventing over-travel, and audible warning devices.

Load Testing and Commissioning Procedures

Systematic testing validates proper installation and safe operation before placing the equipment into service. ASME B30.2 standards require load testing at 125% of rated capacity, held for a minimum of 10 minutes while inspecting all structural and mechanical components. For instance, a 50-ton crane undergoes testing with a 62.5-ton test load, carefully positioned to maximize structural stress.

Testing protocols progress through multiple stages. Initially, functional tests verify all motions operate correctly under no-load conditions, checking hoist, trolley, and bridge movements for smoothness and proper speed. Subsequently, incremental load testing begins at 50% capacity, progressing to 100%, and finally to 125% test load. Throughout testing, engineers monitor for unusual noises, vibrations, excessive deflection, or any indication of improper installation.

Deflection measurements receive particular scrutiny during load tests. Main girders typically deflect approximately L/800 to L/1000 under rated load, where L represents the span length. A 60-foot span should deflect approximately 0.72 to 0.90 inches under full load, returning to original position when unloaded. Permanent deformation indicates structural problems requiring immediate attention before operational approval.

Safety Standards and Regulatory Compliance

Professional double girder overhead crane installation must comply with multiple regulatory frameworks to ensure worker safety and legal operation. OSHA 1910.179 establishes fundamental requirements for overhead cranes, mandating regular inspections, operator training, and maintenance procedures. Specifically, OSHA requires daily visual inspections by operators, monthly documented inspections by designated personnel, and annual comprehensive inspections by qualified engineers.

ASME B30.2 provides detailed technical standards governing design, installation, inspection, testing, maintenance, and operation. These standards address load ratings, safety factors, electrical systems, and operational procedures. Moreover, CMAA Specification #70 classifies cranes by service class (A through F) based on duty cycle and loading patterns, ensuring installations match operational requirements.

State and local building codes may impose additional requirements beyond federal regulations. Consequently, installation contractors must coordinate with local building departments, securing necessary permits and scheduling mandatory inspections. Non-compliance can result in operational shutdowns, financial penalties, and liability exposure in case of accidents.

Cost Analysis and Budget Considerations

Understanding cost components helps facilities develop accurate budgets for double girder overhead crane installation projects. Installation costs typically represent 15-25% of total crane system investment, varying based on facility conditions and project complexity. A recent survey of industrial installations revealed average costs of $45,000 to $85,000 for installing 20-30 ton capacity systems in prepared facilities.

Cost breakdown typically allocates 40-50% to labor, 20-30% to equipment rental (mobile cranes, lifts, specialized tools), 15-25% to materials (fasteners, electrical components, structural modifications), and 10-15% to engineering, permits, and project management. Additionally, facilities should budget 10-15% contingency for unforeseen conditions or scope changes.

Structural modifications significantly impact overall costs. Buildings requiring column reinforcement, foundation work, or roof structure enhancement may incur additional expenses of $30,000 to $150,000 depending on scope. Therefore, comprehensive structural assessment during planning prevents budget surprises during construction.

Common Installation Challenges and Solutions

Even well-planned installations encounter obstacles requiring creative problem-solving. Inadequate overhead clearance ranks among the most frequent issues, particularly in retrofitted facilities. Solutions include lowering floor levels, raising roof structures, or selecting low-headroom crane configurations. Each approach carries cost implications ranging from $15,000 to $200,000 depending on scale.

Existing utility conflicts present another common challenge. HVAC ductwork, electrical conduit, piping, and structural elements often occupy space required for runway beams or crane travel. Consequently, utility relocation becomes necessary, requiring coordination with multiple trades and potentially extending project timelines by 1-3 weeks.

Building column spacing misalignment with crane specifications occasionally occurs, particularly when using standard crane designs in existing facilities. Custom engineering solutions, such as intermediate support structures or modified runway beam spans, resolve these situations. However, custom solutions typically add 3-6 weeks to lead times and increase costs by 15-25% compared to standard configurations.

Real-World Case Study: Automotive Parts Manufacturing Facility

A recent double girder overhead crane installation project at an automotive components manufacturer in Tennessee demonstrates typical project scope and outcomes. The facility required a 40-ton capacity system with 70-foot span to serve a 15,000 square foot machining department. Pre-installation structural evaluation revealed adequate column capacity but insufficient foundation depth, necessitating foundation enhancement before proceeding.

Project execution spanned 42 days from mobilization to final acceptance. Foundation work consumed the first 10 days, followed by runway beam installation over 8 days. Main girder installation occurred during a scheduled production shutdown, completing in 3 days. Electrical work and commissioning required the remaining 21 days, including comprehensive testing and operator training.

Total project cost reached $385,000, breaking down to $240,000 for the crane equipment, $95,000 for installation labor and equipment, $35,000 for structural modifications, and $15,000 for engineering and permitting. The installation improved material handling efficiency by 45%, eliminated forklift traffic in the machining area, and reduced product damage by 60% compared to previous handling methods.

Documentation and Acceptance Procedures

Proper documentation establishes operational baselines and supports ongoing maintenance programs. Installation contractors should provide complete as-built drawings reflecting any field modifications, load test reports with deflection measurements and structural observations, electrical schematics and control panel documentation, maintenance manuals and recommended service schedules, and warranty information covering equipment and installation workmanship.

Acceptance procedures typically involve formal walkthrough with facility representatives, demonstration of all crane functions under load, review of test results and safety features, operator training for designated personnel, and documented sign-off acknowledging satisfactory completion. Furthermore, many facilities implement a 30-90 day warranty period during which the contractor addresses any performance issues or deficiencies.

Maintaining comprehensive records proves invaluable for insurance purposes, regulatory compliance, and future maintenance planning. Digital documentation systems increasingly replace paper files, providing easier access and better organization of inspection reports, maintenance records, and modification history.

Safety Disclaimer: This article provides general information about overhead crane installation for educational purposes. Actual installations must be performed by qualified professionals following all applicable codes, standards, and manufacturer specifications. Consult licensed engineers and certified installation contractors for your specific project requirements.

Technical Specifications Disclaimer: All technical data, tolerances, and specifications referenced herein represent general industry standards and typical applications. Specific projects may require different parameters based on unique conditions, local regulations, or engineering requirements. Always follow manufacturer recommendations and applicable building codes for your installation.

Need Expert Installation Guidance? Contact us for free technical consultation and professional installation quotations.