LH A3 Double-Girder Overhead Crane: Robust Industrial Lifting

Overview of the LH A3 Double-Girder Overhead Crane

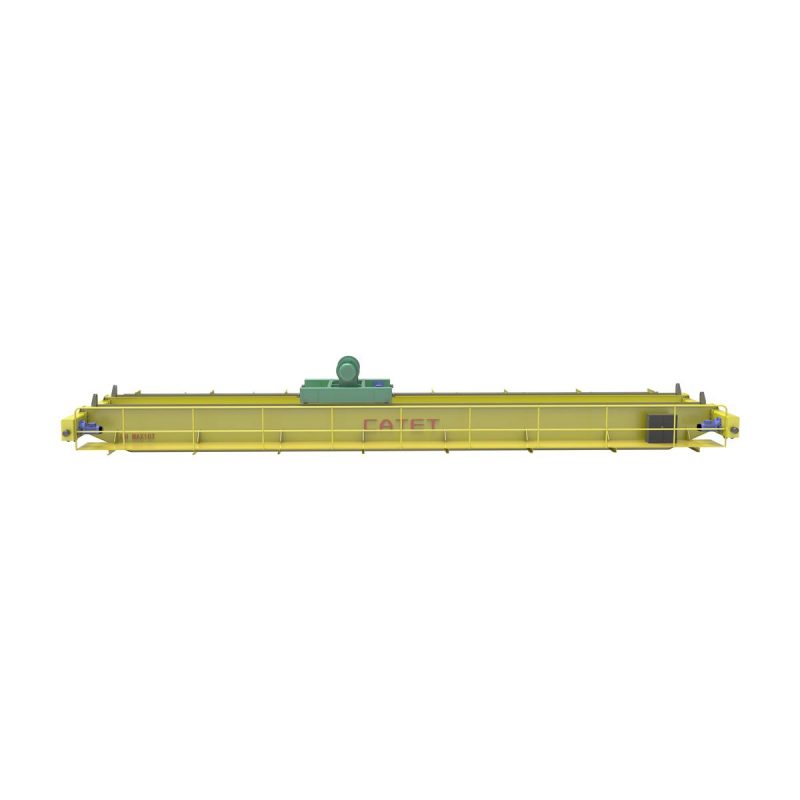

The LH A3 Double-Girder Overhead Crane is a durable and efficient lifting solution crafted for demanding industrial settings. Featuring a welded box-type main beam, end beams, a lifting trolley, and a reliable traveling mechanism, it integrates seamlessly with CD/MD wire rope hoists or chain hoists. The crane supports three synchronized movements: longitudinal bridge travel, lateral trolley movement, and vertical hook lifting, ensuring precise and stable operations.

Its compact design and versatile control options make it ideal for manufacturing plants, steel mills, metallurgical casting facilities, warehouses, power plants, and machining workshops. The LH A3 crane delivers consistent, safe, and efficient lifting for both production and storage environments.

Explore our range of Double-Girder Bridge Crane solutions for additional options.

Applications of the LH A3 Double-Girder Overhead Crane

This crane is engineered for versatility across various industrial applications:

- Steel and metallurgical plants: Handles heavy materials in high-demand settings.

- Machining and assembly workshops: Supports precise equipment handling and assembly.

- Power generation facilities: Facilitates maintenance and material transport in energy plants.

- Warehouses and logistics hubs: Enhances efficiency in loading and unloading operations.

- Equipment manufacturing sites: Ideal for maintenance and production tasks.

Key Advantages of the LH A3 Double-Girder Overhead Crane

The LH A3 crane combines performance and practicality for optimal industrial lifting:

- Compact and high-capacity design: Maximizes space utilization while supporting robust load-bearing.

- Smooth and stable operation: Features frequency inverter control and a three-in-one motor reducer for low inertia and seamless acceleration.

- Durable construction: Built with automatic welding and non-destructive testing for long-term reliability.

- Low-noise performance: Smooth braking reduces vibration and noise, enhancing operator comfort.

- Premium components: Equipped with top-tier motors, reducers, and brakes from trusted domestic and international brands.

- Flexible control options: Offers pendant, wireless remote, or operator cab controls for operational ease.

- Advanced safety systems: Includes buffers, limit switches, overload protection, voltage safeguards, emergency stops, and anti-collision devices.

Technical Features

- Working Level: A3, optimized for medium-duty industrial applications.

- Trolley Mechanism: Robust design with hoist, hook, pulley, and rigid frame for stability.

- Electrical System: Variable frequency converter enables energy-efficient operation, overload protection, and adjustable lifting speeds.

- Drive Protection: IP54/IP55 protection class with F-class insulation for dependable performance.

- Safety Assurance: Equipped with height limiters, polyurethane buffers, overload limiters, and emergency stop devices for secure operations.

Why Choose the LH A3 Double-Girder Overhead Crane?

The LH A3 crane is a reliable, cost-effective solution for industrial lifting needs. Its compliance with FEM standards and EU CE regulations ensures safety and quality. With a focus on durability, low maintenance, and energy efficiency, this crane is perfect for steel plants, workshops, and logistics hubs, delivering long-term value and operational excellence.

For more details or to request a quote, contact our team today.

Reviews

There are no reviews yet.